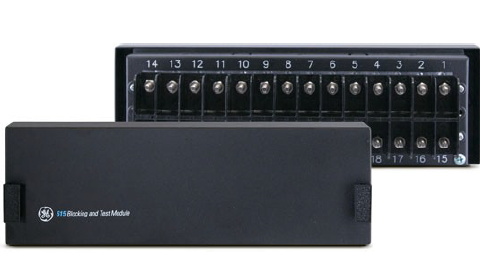

GE Fanuc IC200ALG326 Versamax PLC Modular Control System

Introducing the GE Fanuc – a cutting-edge solution in the realm of industrial automation, designed to cater to the diverse needs of modern manufacturing and process control environments. Renowned for its robust performance, reliability, and advanced technology, the GE Fanuc stands out as a premier choice for businesses looking to enhance operational efficiency and productivity.

Key technical features of the GE Fanuc encompass its exceptional processing power, versatile connectivity options, and scalable architecture. With a powerful CPU, the GE Fanuc ensures rapid data processing and real-time control, which is crucial for complex manufacturing processes. The unit supports multiple communication protocols, allowing seamless integration with existing systems and devices. Enhanced with a range of I/O modules, including the IC697MDL250 for discrete input and output control, and the IC693CPU374 for high-performance processing, this model is adept at handling various automation tasks with precision and ease.

The GE Fanuc is designed for a myriad of usage scenarios across different sectors. In manufacturing environments, it can be utilized for machine control, monitoring production lines, and optimizing workflows. Its real-time capabilities make it perfect for assembly lines where timing is essential. Moreover, in the energy sector, the GE Fanuc can facilitate the monitoring and control of power generation processes, ensuring efficiency and safety. The unit is equally effective in food processing, where stringent quality control is paramount, and in pharmaceuticals, where regulatory compliance demands rigorous process oversight.

When comparing the GE Fanuc to other models within the GE family, such as the GE IS200TBCIH1BBC and the GE IS220PPROS1B, the Fanuc model emphasizes enhanced scalability and connectivity. While the IS200 and IS220 series are exceptional for specific applications, the GE Fanuc is designed to provide broader versatility across multiple applications. For instance, the IC660ELB912G is known for its strong performance in control systems, but the GE Fanuc surpasses it by offering a more comprehensive suite of automation capabilities that is adaptable to various operational needs.

In addition to its core features, the GE Fanuc is compatible with a selection of related models that enhance its functionality. The GE IS230SNIDH1A, for instance, serves as an optimal partner for networking and communication needs, while the GE PRG-MODEM provides essential remote access capabilities. Other complementary models include the GE DS200CTBAG1ADD, which supports additional control systems, and the GE IC670MDL640, known for its robust I/O capabilities. The integration with the GE EVMECNTM13 adds an extra layer of versatility, making it ideal for sophisticated control tasks.

The GE Fanuc excels not only in performance but also in user-friendly features designed to simplify operation and maintenance. Its intuitive interface allows operators to monitor system status and make adjustments in real-time, significantly reducing downtime and enhancing productivity. Furthermore, the model is engineered for longevity, ensuring that it withstands the rigors of demanding industrial environments.

In conclusion, the GE Fanuc emerges as a powerhouse in the world of GE automation products, offering unparalleled performance, adaptability, and reliability. It is an ideal choice for businesses seeking to elevate their automation capabilities, streamline operations, and achieve their production goals. Whether you are in manufacturing, energy, food processing, or pharmaceuticals, the GE Fanuc meets the demands of your industry with precision and efficiency. Upgrade your automation strategy with the GE Fanuc and experience the future of industrial control today.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key technical features of the GE Fanuc encompass its exceptional processing power, versatile connectivity options, and scalable architecture. With a powerful CPU, the GE Fanuc ensures rapid data processing and real-time control, which is crucial for complex manufacturing processes. The unit supports multiple communication protocols, allowing seamless integration with existing systems and devices. Enhanced with a range of I/O modules, including the IC697MDL250 for discrete input and output control, and the IC693CPU374 for high-performance processing, this model is adept at handling various automation tasks with precision and ease.

The GE Fanuc is designed for a myriad of usage scenarios across different sectors. In manufacturing environments, it can be utilized for machine control, monitoring production lines, and optimizing workflows. Its real-time capabilities make it perfect for assembly lines where timing is essential. Moreover, in the energy sector, the GE Fanuc can facilitate the monitoring and control of power generation processes, ensuring efficiency and safety. The unit is equally effective in food processing, where stringent quality control is paramount, and in pharmaceuticals, where regulatory compliance demands rigorous process oversight.

When comparing the GE Fanuc to other models within the GE family, such as the GE IS200TBCIH1BBC and the GE IS220PPROS1B, the Fanuc model emphasizes enhanced scalability and connectivity. While the IS200 and IS220 series are exceptional for specific applications, the GE Fanuc is designed to provide broader versatility across multiple applications. For instance, the IC660ELB912G is known for its strong performance in control systems, but the GE Fanuc surpasses it by offering a more comprehensive suite of automation capabilities that is adaptable to various operational needs.

In addition to its core features, the GE Fanuc is compatible with a selection of related models that enhance its functionality. The GE IS230SNIDH1A, for instance, serves as an optimal partner for networking and communication needs, while the GE PRG-MODEM provides essential remote access capabilities. Other complementary models include the GE DS200CTBAG1ADD, which supports additional control systems, and the GE IC670MDL640, known for its robust I/O capabilities. The integration with the GE EVMECNTM13 adds an extra layer of versatility, making it ideal for sophisticated control tasks.

The GE Fanuc excels not only in performance but also in user-friendly features designed to simplify operation and maintenance. Its intuitive interface allows operators to monitor system status and make adjustments in real-time, significantly reducing downtime and enhancing productivity. Furthermore, the model is engineered for longevity, ensuring that it withstands the rigors of demanding industrial environments.

In conclusion, the GE Fanuc emerges as a powerhouse in the world of GE automation products, offering unparalleled performance, adaptability, and reliability. It is an ideal choice for businesses seeking to elevate their automation capabilities, streamline operations, and achieve their production goals. Whether you are in manufacturing, energy, food processing, or pharmaceuticals, the GE Fanuc meets the demands of your industry with precision and efficiency. Upgrade your automation strategy with the GE Fanuc and experience the future of industrial control today.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.