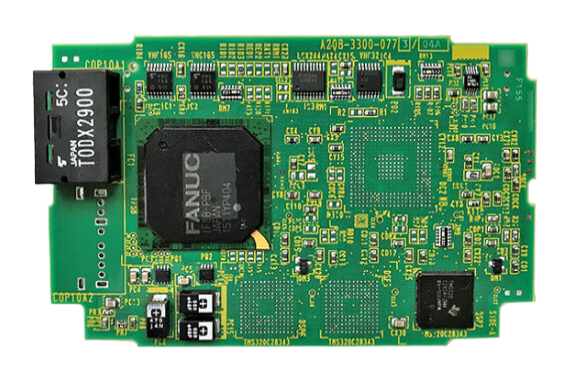

GE FANUC DS200SDCIG2AFB Mark V Control Board

Introducing the GE FANUC: a pinnacle of performance and reliability in the world of industrial automation. As part of the renowned GE family, the GE FANUC stands out with its exceptional technical features and versatile applications, making it an indispensable asset for a wide range of industrial environments.

Key Technical Features

The GE FANUC is engineered with state-of-the-art technology that ensures optimal performance in demanding conditions. One of its key features is its robust processing power, enabling rapid data processing and execution of complex control tasks. It utilizes advanced communication protocols, ensuring seamless integration with other GE automation products and third-party systems, enhancing interoperability across your operations.

This model is equipped with extensive I/O capabilities, allowing for easy configuration and scalability as your automation needs evolve. The GE FANUC supports a variety of input and output modules, providing flexibility to accommodate diverse applications. Additionally, it features built-in diagnostics and troubleshooting tools, facilitating proactive maintenance and reducing downtime.

Another standout feature is the user-friendly interface, which simplifies monitoring and control, making it accessible even for operators with minimal technical expertise. With its compact design, the GE FANUC fits easily into existing control panels, optimizing space without compromising functionality.

Usage Scenarios

The GE FANUC is ideal for a myriad of industrial applications, including manufacturing, process control, and energy management. Its robust design and reliability make it perfect for continuous operations in environments such as assembly lines, packaging systems, and robotic automation.

In manufacturing, the GE FANUC can manage and coordinate multiple machines, ensuring synchronized operations for increased productivity. In process control, it monitors and adjusts parameters in real-time, maintaining optimal performance and product quality. Its role in energy management involves monitoring consumption patterns and optimizing usage to enhance efficiency and reduce costs.

Whether you are automating a small workshop or a large-scale production facility, the GE FANUC adapts to your specific requirements, providing the scalability necessary for future growth.

Comparison with Other Models

When compared to other models in the GE family, such as the GE SR750 and GE IS200DSPXH2DBD, the GE FANUC offers a balance of advanced features and user accessibility. While the GE SR750 is known for its high-speed processing capabilities, the GE FANUC provides a more versatile solution with a broad range of I/O options, making it suitable for varied applications.

In contrast to the GE IS200EDFFH1ABA, which excels in high-performance environments, the GE FANUC shines with its user-friendly interface and ease of integration, making it a preferred choice for facilities looking to upgrade without extensive retraining.

Related Models

The GE FANUC is part of a comprehensive suite of GE automation products that enhance operational efficiency and reliability. Related models include the GE IC697MDL740, GE IS200DSFCG1AEB, GE IC660BBA020, GE DS200DDTBG2A, GE IS200DSPXH2DBD, GE ALG, GE IS220PPDAH1A,

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE FANUC is engineered with state-of-the-art technology that ensures optimal performance in demanding conditions. One of its key features is its robust processing power, enabling rapid data processing and execution of complex control tasks. It utilizes advanced communication protocols, ensuring seamless integration with other GE automation products and third-party systems, enhancing interoperability across your operations.

This model is equipped with extensive I/O capabilities, allowing for easy configuration and scalability as your automation needs evolve. The GE FANUC supports a variety of input and output modules, providing flexibility to accommodate diverse applications. Additionally, it features built-in diagnostics and troubleshooting tools, facilitating proactive maintenance and reducing downtime.

Another standout feature is the user-friendly interface, which simplifies monitoring and control, making it accessible even for operators with minimal technical expertise. With its compact design, the GE FANUC fits easily into existing control panels, optimizing space without compromising functionality.

Usage Scenarios

The GE FANUC is ideal for a myriad of industrial applications, including manufacturing, process control, and energy management. Its robust design and reliability make it perfect for continuous operations in environments such as assembly lines, packaging systems, and robotic automation.

In manufacturing, the GE FANUC can manage and coordinate multiple machines, ensuring synchronized operations for increased productivity. In process control, it monitors and adjusts parameters in real-time, maintaining optimal performance and product quality. Its role in energy management involves monitoring consumption patterns and optimizing usage to enhance efficiency and reduce costs.

Whether you are automating a small workshop or a large-scale production facility, the GE FANUC adapts to your specific requirements, providing the scalability necessary for future growth.

Comparison with Other Models

When compared to other models in the GE family, such as the GE SR750 and GE IS200DSPXH2DBD, the GE FANUC offers a balance of advanced features and user accessibility. While the GE SR750 is known for its high-speed processing capabilities, the GE FANUC provides a more versatile solution with a broad range of I/O options, making it suitable for varied applications.

In contrast to the GE IS200EDFFH1ABA, which excels in high-performance environments, the GE FANUC shines with its user-friendly interface and ease of integration, making it a preferred choice for facilities looking to upgrade without extensive retraining.

Related Models

The GE FANUC is part of a comprehensive suite of GE automation products that enhance operational efficiency and reliability. Related models include the GE IC697MDL740, GE IS200DSFCG1AEB, GE IC660BBA020, GE DS200DDTBG2A, GE IS200DSPXH2DBD, GE ALG, GE IS220PPDAH1A,

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.