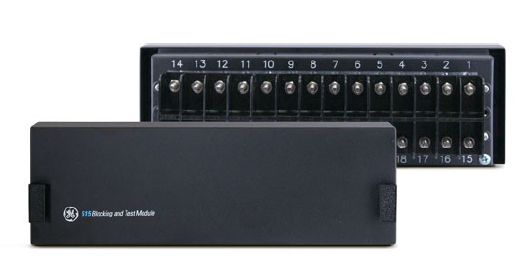

GE Fanuc DS200CDBAG1B Mark V Contactor Driver Board

Introducing the GE Fanuc Model, a flagship offering from GE that embodies cutting-edge technology and unparalleled reliability in the world of automation. Designed for a diverse range of industrial applications, this model stands out for its robust technical features that cater to both small-scale operations and large industrial environments.

Key Technical Features:

The GE Fanuc model is engineered with advanced processing capabilities that ensure high-speed data handling and real-time monitoring. Its powerful CPU architecture guarantees efficient operation, while its extensive I/O options allow for seamless integration with existing systems. The model supports various communication protocols, making it compatible with a wide array of GE automation products, enhancing its versatility. Users will benefit from features such as built-in redundancy, which minimizes downtime and maximizes operational continuity. Additionally, the GE Fanuc model is equipped with comprehensive diagnostic tools that enable proactive maintenance and rapid troubleshooting, ensuring that your systems run smoothly.

Usage Scenarios:

The GE Fanuc model excels in multiple industrial settings, including manufacturing, process control, and energy management. It is particularly suited for environments where precision and reliability are non-negotiable. For instance, in a manufacturing plant, the GE Fanuc model can be employed to monitor assembly lines, optimize production schedules, and maintain quality control, all while providing real-time data analytics. In process control applications, it can manage complex workflows, ensuring that each step is executed flawlessly. Furthermore, in energy management, the GE Fanuc model can play a crucial role in monitoring energy consumption and implementing efficiency measures, contributing to sustainability goals.

Comparison with Other Models:

When compared to other models within the GE lineup, such as the GE SR750 and GE IS200DSPXH2DBD, the GE Fanuc model stands out for its enhanced processing capabilities and scalability. While the SR750 is excellent for smaller applications, the Fanuc model provides greater flexibility for larger operations, supporting a wider range of I/O configurations and communication protocols. In contrast to the GE IC697MDL740, which is primarily focused on discrete I/O applications, the GE Fanuc model offers a more comprehensive solution suitable for both discrete and process control environments. This makes it an ideal choice for businesses looking to future-proof their automation systems.

Related Models:

For those interested in exploring additional options within the GE automation products range, consider the following models: GE IS200DSFCG1AEB, GE IC660BBA020, GE DS200DDTBG2A, GE IS200DSPXH2DBD, GE IC693APU301, GE DS3800HSAB, GE IC200CPU005, GE IC3600A0AHIC, GE IS200EDFFH1ABA, and GE IC695CPE310-ABAH. Each of these models brings unique features and capabilities to the table, allowing users to select the best fit according to their specific needs.

SEO Keywords:

As you explore the advantages of the GE Fanuc model, it’s important to consider the broader context of GE automation products.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE Fanuc model is engineered with advanced processing capabilities that ensure high-speed data handling and real-time monitoring. Its powerful CPU architecture guarantees efficient operation, while its extensive I/O options allow for seamless integration with existing systems. The model supports various communication protocols, making it compatible with a wide array of GE automation products, enhancing its versatility. Users will benefit from features such as built-in redundancy, which minimizes downtime and maximizes operational continuity. Additionally, the GE Fanuc model is equipped with comprehensive diagnostic tools that enable proactive maintenance and rapid troubleshooting, ensuring that your systems run smoothly.

Usage Scenarios:

The GE Fanuc model excels in multiple industrial settings, including manufacturing, process control, and energy management. It is particularly suited for environments where precision and reliability are non-negotiable. For instance, in a manufacturing plant, the GE Fanuc model can be employed to monitor assembly lines, optimize production schedules, and maintain quality control, all while providing real-time data analytics. In process control applications, it can manage complex workflows, ensuring that each step is executed flawlessly. Furthermore, in energy management, the GE Fanuc model can play a crucial role in monitoring energy consumption and implementing efficiency measures, contributing to sustainability goals.

Comparison with Other Models:

When compared to other models within the GE lineup, such as the GE SR750 and GE IS200DSPXH2DBD, the GE Fanuc model stands out for its enhanced processing capabilities and scalability. While the SR750 is excellent for smaller applications, the Fanuc model provides greater flexibility for larger operations, supporting a wider range of I/O configurations and communication protocols. In contrast to the GE IC697MDL740, which is primarily focused on discrete I/O applications, the GE Fanuc model offers a more comprehensive solution suitable for both discrete and process control environments. This makes it an ideal choice for businesses looking to future-proof their automation systems.

Related Models:

For those interested in exploring additional options within the GE automation products range, consider the following models: GE IS200DSFCG1AEB, GE IC660BBA020, GE DS200DDTBG2A, GE IS200DSPXH2DBD, GE IC693APU301, GE DS3800HSAB, GE IC200CPU005, GE IC3600A0AHIC, GE IS200EDFFH1ABA, and GE IC695CPE310-ABAH. Each of these models brings unique features and capabilities to the table, allowing users to select the best fit according to their specific needs.

SEO Keywords:

As you explore the advantages of the GE Fanuc model, it’s important to consider the broader context of GE automation products.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.