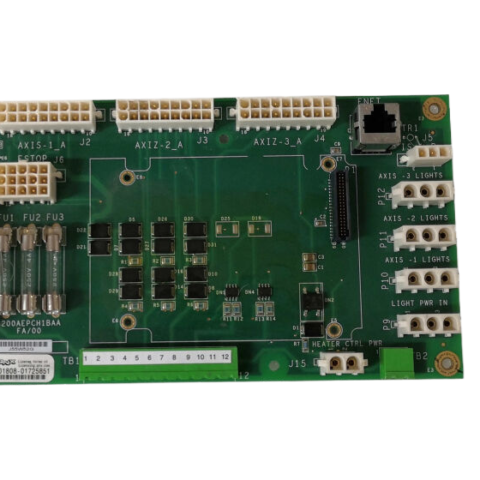

GE Fanuc AID16D A03B-0807-C104 DC Input Module High-Performance DC Input Solution for Industrial Automation

Introducing the GE Fanuc, a hallmark of reliability and performance in the realm of industrial automation. This model exemplifies GE's commitment to innovation and excellence, providing advanced solutions tailored to meet the diverse needs of various industries.

Key Technical Features:

The GE Fanuc boasts a robust architecture designed for high-performance applications. With its cutting-edge processing capabilities, it ensures seamless operation across different platforms. The device integrates advanced communication protocols, enhancing connectivity with other GE automation products. Notable features include a high-speed processor, extensive memory options for data storage, and versatile input/output configurations that can accommodate a wide range of sensors and actuators. Additionally, the model supports multiple programming languages, allowing for greater flexibility in system design and implementation.

Usage Scenarios:

The GE Fanuc is ideal for a variety of industrial environments, including manufacturing, energy production, and transportation systems. Its versatility makes it suitable for applications such as process control, machine automation, and system monitoring. For instance, in a manufacturing plant, the GE Fanuc can orchestrate the operations of robotic arms, conveyor systems, and quality control mechanisms, ensuring optimal productivity and efficiency. In the energy sector, it plays a crucial role in monitoring and controlling power generation processes, contributing to enhanced safety and reliability. Its adaptability also makes it a perfect fit for transportation systems, where it can manage traffic signals, monitor vehicle performance, and ensure passenger safety.

Comparison with Other Models:

When compared to other models in the GE lineup, such as the GE IS200TBCIH1BBC and GE IC697MDL250, the GE Fanuc stands out due to its superior processing speed and greater flexibility in configuration. While the IS200TBCIH1BBC is tailored for specific control tasks, the GE Fanuc offers a broader spectrum of functionality, making it a more versatile choice for complex automation requirements. In contrast to the GE IC697MDL250, which is known for its robust input/output capabilities, the GE Fanuc enhances this with advanced communication features that facilitate integration with modern automation systems.

Reference to Related Models:

To provide a comprehensive view of the GE automation product ecosystem, the GE Fanuc can be compared with several related models:

1. GE IS220PPROS1B – Ideal for process control applications.

2. GE CT7P70500470CW24 – Offers unique interfacing capabilities.

3. GE EVMECNTM13 – Known for its effective monitoring solutions.

4. GE IS215UCVEH2AB – Designed for user-friendly applications.

5. GE R-TPD3 – Excellent in real-time processing tasks.

6. GE IC697MDL653 – Focused on high-density input/output configurations.

7. GE IS200TPROH1BBB – A robust solution for turbine control.

8. GE IC660ELB912G – Features enhanced communication options.

9. GE IC698CMX016 – A compact yet powerful automation controller.

10. GE DS200CTBAG1ADD – Known for its reliability in critical applications.

In essence, the GE Fanuc represents a significant advancement in automation technology, providing users with an unparalleled combination of speed, efficiency, and adaptability. Whether you are looking to enhance productivity in a manufacturing environment or streamline processes in the energy sector, the GE Fanuc is your go-to solution. Its comprehensive features and broad application range make it a standout choice among GE automation products, ensuring your operations run smoothly and effectively. Elevate your industrial automation capabilities with the GE Fanuc, where innovation meets reliability.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE Fanuc boasts a robust architecture designed for high-performance applications. With its cutting-edge processing capabilities, it ensures seamless operation across different platforms. The device integrates advanced communication protocols, enhancing connectivity with other GE automation products. Notable features include a high-speed processor, extensive memory options for data storage, and versatile input/output configurations that can accommodate a wide range of sensors and actuators. Additionally, the model supports multiple programming languages, allowing for greater flexibility in system design and implementation.

Usage Scenarios:

The GE Fanuc is ideal for a variety of industrial environments, including manufacturing, energy production, and transportation systems. Its versatility makes it suitable for applications such as process control, machine automation, and system monitoring. For instance, in a manufacturing plant, the GE Fanuc can orchestrate the operations of robotic arms, conveyor systems, and quality control mechanisms, ensuring optimal productivity and efficiency. In the energy sector, it plays a crucial role in monitoring and controlling power generation processes, contributing to enhanced safety and reliability. Its adaptability also makes it a perfect fit for transportation systems, where it can manage traffic signals, monitor vehicle performance, and ensure passenger safety.

Comparison with Other Models:

When compared to other models in the GE lineup, such as the GE IS200TBCIH1BBC and GE IC697MDL250, the GE Fanuc stands out due to its superior processing speed and greater flexibility in configuration. While the IS200TBCIH1BBC is tailored for specific control tasks, the GE Fanuc offers a broader spectrum of functionality, making it a more versatile choice for complex automation requirements. In contrast to the GE IC697MDL250, which is known for its robust input/output capabilities, the GE Fanuc enhances this with advanced communication features that facilitate integration with modern automation systems.

Reference to Related Models:

To provide a comprehensive view of the GE automation product ecosystem, the GE Fanuc can be compared with several related models:

1. GE IS220PPROS1B – Ideal for process control applications.

2. GE CT7P70500470CW24 – Offers unique interfacing capabilities.

3. GE EVMECNTM13 – Known for its effective monitoring solutions.

4. GE IS215UCVEH2AB – Designed for user-friendly applications.

5. GE R-TPD3 – Excellent in real-time processing tasks.

6. GE IC697MDL653 – Focused on high-density input/output configurations.

7. GE IS200TPROH1BBB – A robust solution for turbine control.

8. GE IC660ELB912G – Features enhanced communication options.

9. GE IC698CMX016 – A compact yet powerful automation controller.

10. GE DS200CTBAG1ADD – Known for its reliability in critical applications.

In essence, the GE Fanuc represents a significant advancement in automation technology, providing users with an unparalleled combination of speed, efficiency, and adaptability. Whether you are looking to enhance productivity in a manufacturing environment or streamline processes in the energy sector, the GE Fanuc is your go-to solution. Its comprehensive features and broad application range make it a standout choice among GE automation products, ensuring your operations run smoothly and effectively. Elevate your industrial automation capabilities with the GE Fanuc, where innovation meets reliability.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.