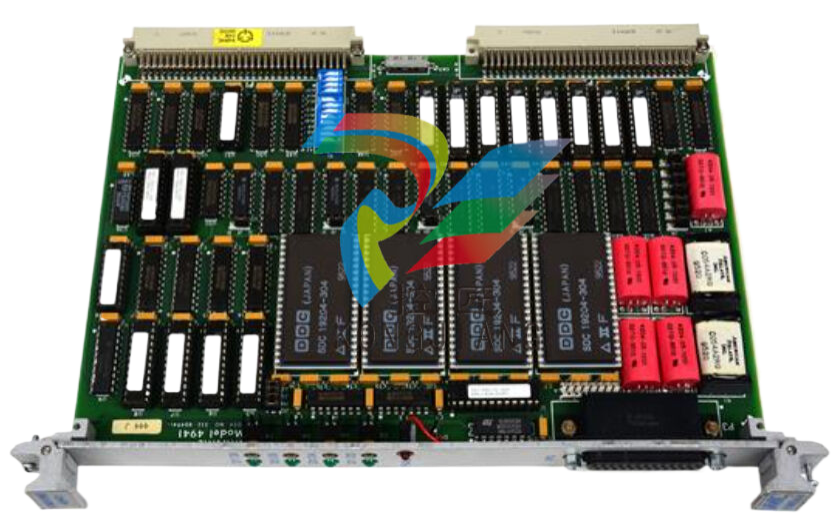

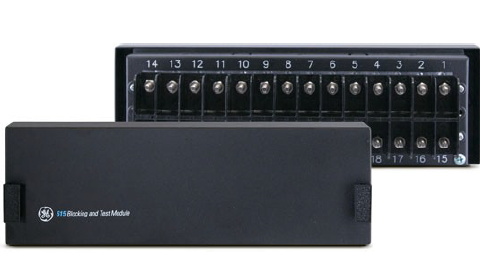

GE FANUC 78005196 TGT Expansion Axis Module Precision and Performance for Industrial Applications

Introducing the GE FANUC, a pinnacle of innovation in the realm of industrial automation. Renowned for its reliability and performance, the GE FANUC series is engineered to meet the demanding needs of modern manufacturing and process control environments. This robust line of automation products integrates seamlessly into various applications, ensuring optimal efficiency and productivity.

Key Technical Features:

The GE FANUC series boasts an array of advanced technical features designed to enhance operational capabilities. Key among these is its high-speed processing capability, which allows for rapid data handling and real-time decision-making. With a powerful CPU architecture, the GE FANUC guarantees quick response times, making it ideal for time-sensitive applications.

Additionally, the GE FANUC supports a wide variety of communication protocols, including Ethernet, Modbus, and Profibus, enabling seamless integration with other systems and devices within your automation landscape. Its modular design allows for easy upgrades and scalability, accommodating future growth without significant downtime. The series also includes extensive I/O options, ensuring compatibility with a broad range of sensors and actuators.

Usage Scenarios:

The versatility of the GE FANUC series makes it suitable for various industrial applications. From discrete manufacturing processes to complex continuous operations, this product line can handle it all. Industries such as automotive, food and beverage, pharmaceuticals, and energy can all benefit from the reliability and efficiency offered by GE automation products.

For instance, in a manufacturing environment, the GE FANUC can be used to control assembly lines, monitor machine performance, and manage production schedules. In the energy sector, it plays a crucial role in monitoring and controlling power generation processes, ensuring optimal performance and safety standards. The adaptability of the GE FANUC allows it to fit into diverse configurations, whether as part of a large-scale automation system or as a standalone solution.

Comparison with Other Models:

When comparing the GE FANUC to other models within the GE automation product range, several distinctions emerge. For example, the GE IS200TBCIH1BBC focuses on specialized control applications, while the GE IC697MDL250 is designed for more straightforward relay control tasks. In contrast, the GE FANUC offers a balance of processing power and connectivity options, making it a versatile choice for varied applications.

Another noteworthy comparison is with the GE IS220PAICH2A, which is geared towards advanced process control. While both models excel in their respective areas, the GE FANUC stands out with its broader compatibility and modular design, making it easier to adapt to evolving industrial requirements.

Related Models:

For those interested in exploring other options within the GE automation ecosystem, consider the following related models: GE IS220PPROS1B, GE CT7P70500470CW24, GE EVMECNTM13, GE R-TPD3, GE IS215UCVEH2AB, GE IC660ELB912G, GE IS200TPROH1BBB, GE IS230SNIDH1A, GE IC670MDL740J, and GE IC693CPU374. Each of these models has unique features tailored to specific applications, but all share the hallmark of reliability and innovation synonymous with GE automation products.

Conclusion:

In conclusion, the GE FANUC series is a testament to GE's commitment to advancing automation technology. With its powerful processing capabilities, versatile usage scenarios, and robust feature set, it stands as a premier choice for industries seeking to enhance their operational efficiency. Whether you are implementing a new system or upgrading an existing one, GE FANUC is the ideal solution for your automation needs. Embrace the future of industrial automation with the unparalleled performance of GE FANUC, where precision meets reliability.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE FANUC series boasts an array of advanced technical features designed to enhance operational capabilities. Key among these is its high-speed processing capability, which allows for rapid data handling and real-time decision-making. With a powerful CPU architecture, the GE FANUC guarantees quick response times, making it ideal for time-sensitive applications.

Additionally, the GE FANUC supports a wide variety of communication protocols, including Ethernet, Modbus, and Profibus, enabling seamless integration with other systems and devices within your automation landscape. Its modular design allows for easy upgrades and scalability, accommodating future growth without significant downtime. The series also includes extensive I/O options, ensuring compatibility with a broad range of sensors and actuators.

Usage Scenarios:

The versatility of the GE FANUC series makes it suitable for various industrial applications. From discrete manufacturing processes to complex continuous operations, this product line can handle it all. Industries such as automotive, food and beverage, pharmaceuticals, and energy can all benefit from the reliability and efficiency offered by GE automation products.

For instance, in a manufacturing environment, the GE FANUC can be used to control assembly lines, monitor machine performance, and manage production schedules. In the energy sector, it plays a crucial role in monitoring and controlling power generation processes, ensuring optimal performance and safety standards. The adaptability of the GE FANUC allows it to fit into diverse configurations, whether as part of a large-scale automation system or as a standalone solution.

Comparison with Other Models:

When comparing the GE FANUC to other models within the GE automation product range, several distinctions emerge. For example, the GE IS200TBCIH1BBC focuses on specialized control applications, while the GE IC697MDL250 is designed for more straightforward relay control tasks. In contrast, the GE FANUC offers a balance of processing power and connectivity options, making it a versatile choice for varied applications.

Another noteworthy comparison is with the GE IS220PAICH2A, which is geared towards advanced process control. While both models excel in their respective areas, the GE FANUC stands out with its broader compatibility and modular design, making it easier to adapt to evolving industrial requirements.

Related Models:

For those interested in exploring other options within the GE automation ecosystem, consider the following related models: GE IS220PPROS1B, GE CT7P70500470CW24, GE EVMECNTM13, GE R-TPD3, GE IS215UCVEH2AB, GE IC660ELB912G, GE IS200TPROH1BBB, GE IS230SNIDH1A, GE IC670MDL740J, and GE IC693CPU374. Each of these models has unique features tailored to specific applications, but all share the hallmark of reliability and innovation synonymous with GE automation products.

Conclusion:

In conclusion, the GE FANUC series is a testament to GE's commitment to advancing automation technology. With its powerful processing capabilities, versatile usage scenarios, and robust feature set, it stands as a premier choice for industries seeking to enhance their operational efficiency. Whether you are implementing a new system or upgrading an existing one, GE FANUC is the ideal solution for your automation needs. Embrace the future of industrial automation with the unparalleled performance of GE FANUC, where precision meets reliability.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.