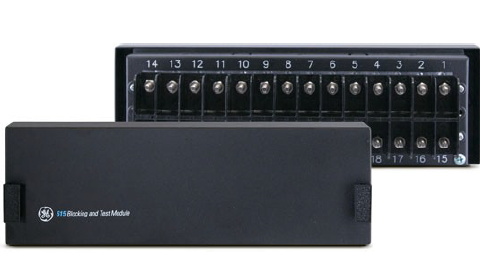

GE Fanuc 531X179PLMAKG1 Advanced PAC System; GE-FANUC Manufacturer

Introducing the GE Fanuc, a pinnacle of reliability and innovation in the realm of automation products. Designed to meet the rigorous demands of industrial applications, the GE Fanuc model integrates cutting-edge technology with user-friendly features, making it an essential asset for any automation environment.

Key Technical Features:

The GE Fanuc boasts an array of impressive technical specifications that set it apart in the automation landscape. With a robust processing capability, it supports a wide range of I/O configurations, enabling seamless integration with existing systems. The model is equipped with advanced networking capabilities, facilitating efficient communication across devices and systems. Its compact design allows for easy installation in constrained spaces, while its durable construction ensures longevity even in harsh industrial environments.

This model features an intuitive interface that simplifies programming and operation, allowing users to quickly adapt and optimize their automation processes. Additionally, the GE Fanuc incorporates state-of-the-art diagnostic tools that provide real-time monitoring and troubleshooting, significantly reducing downtime and enhancing productivity. With support for various communication protocols, including Ethernet/IP and Modbus, the GE Fanuc integrates effortlessly with other GE automation products and third-party devices, ensuring versatility across multiple applications.

Usage Scenarios:

The GE Fanuc is engineered to excel in diverse industrial scenarios. Whether used in manufacturing, oil and gas, water treatment, or packaging, this model proves invaluable in streamlining operations and enhancing efficiency. In manufacturing settings, the GE Fanuc can manage complex assembly lines, coordinating multiple robotic systems to optimize production flow. In the oil and gas sector, it can monitor and control critical processes, ensuring safety and compliance with industry regulations.

Moreover, in water treatment facilities, the GE Fanuc serves as a central control unit, managing pumps, valves, and other equipment to maintain optimal water quality. Its adaptability makes it suitable for various applications, from small-scale operations to large industrial plants, illustrating its capability to meet the unique demands of any sector.

Comparison with Other Models:

When comparing the GE Fanuc to other models within the GE family, such as the GE SR750 or the GE IC697MDL740, it becomes evident that the GE Fanuc offers a superior balance of performance and flexibility. While the SR750 is renowned for its processing speed, the GE Fanuc shines in its versatility and ease of integration with existing systems. In contrast to the GE IC200CPU005, which is more suited for basic applications, the GE Fanuc stands out with its advanced features and robust networking capabilities.

Additionally, models like the GE IS200DSPXH2DBD and GE IC693APU301 focus on specialized functions, whereas the GE Fanuc is designed as a comprehensive solution applicable across a wider range of industries. This versatility is a significant advantage, allowing businesses to invest in a single model that can adapt as their automation needs evolve.

Related Models:

For those exploring the GE automation product line, several related models complement the capabilities of the GE Fanuc. These include the GE DS200DDTBG2A, which excels in data processing

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE Fanuc boasts an array of impressive technical specifications that set it apart in the automation landscape. With a robust processing capability, it supports a wide range of I/O configurations, enabling seamless integration with existing systems. The model is equipped with advanced networking capabilities, facilitating efficient communication across devices and systems. Its compact design allows for easy installation in constrained spaces, while its durable construction ensures longevity even in harsh industrial environments.

This model features an intuitive interface that simplifies programming and operation, allowing users to quickly adapt and optimize their automation processes. Additionally, the GE Fanuc incorporates state-of-the-art diagnostic tools that provide real-time monitoring and troubleshooting, significantly reducing downtime and enhancing productivity. With support for various communication protocols, including Ethernet/IP and Modbus, the GE Fanuc integrates effortlessly with other GE automation products and third-party devices, ensuring versatility across multiple applications.

Usage Scenarios:

The GE Fanuc is engineered to excel in diverse industrial scenarios. Whether used in manufacturing, oil and gas, water treatment, or packaging, this model proves invaluable in streamlining operations and enhancing efficiency. In manufacturing settings, the GE Fanuc can manage complex assembly lines, coordinating multiple robotic systems to optimize production flow. In the oil and gas sector, it can monitor and control critical processes, ensuring safety and compliance with industry regulations.

Moreover, in water treatment facilities, the GE Fanuc serves as a central control unit, managing pumps, valves, and other equipment to maintain optimal water quality. Its adaptability makes it suitable for various applications, from small-scale operations to large industrial plants, illustrating its capability to meet the unique demands of any sector.

Comparison with Other Models:

When comparing the GE Fanuc to other models within the GE family, such as the GE SR750 or the GE IC697MDL740, it becomes evident that the GE Fanuc offers a superior balance of performance and flexibility. While the SR750 is renowned for its processing speed, the GE Fanuc shines in its versatility and ease of integration with existing systems. In contrast to the GE IC200CPU005, which is more suited for basic applications, the GE Fanuc stands out with its advanced features and robust networking capabilities.

Additionally, models like the GE IS200DSPXH2DBD and GE IC693APU301 focus on specialized functions, whereas the GE Fanuc is designed as a comprehensive solution applicable across a wider range of industries. This versatility is a significant advantage, allowing businesses to invest in a single model that can adapt as their automation needs evolve.

Related Models:

For those exploring the GE automation product line, several related models complement the capabilities of the GE Fanuc. These include the GE DS200DDTBG2A, which excels in data processing

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.