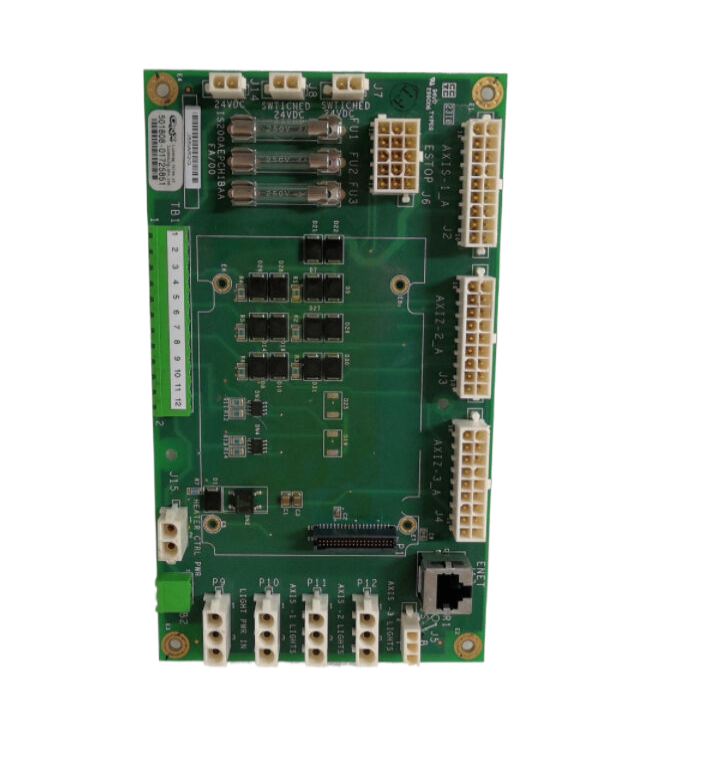

GE FANUC 369-HI-R-0-0-0-0-E Industrial Automation Control Module

Introducing the GE FANUC: a cornerstone of industrial automation that embodies reliability, performance, and innovation. Designed to meet the rigorous demands of modern manufacturing and process control, the GE FANUC is a versatile solution that integrates seamlessly into various applications, ensuring optimal efficiency and productivity.

Key Technical Features:

The GE FANUC model boasts a robust architecture that includes high-speed processing capabilities, advanced input/output modules, and extensive networking options. With its high-performance CPU, the GE FANUC processes complex algorithms swiftly, reducing downtime and enhancing operational throughput. The model supports a wide array of communication protocols, making it highly adaptable to existing systems. Additionally, the GE FANUC features comprehensive diagnostic tools that facilitate real-time monitoring and troubleshooting, ensuring that your operations run smoothly.

One of the standout features is its scalability, allowing businesses to expand their automation capabilities without overhauling existing infrastructure. The GE FANUC's modular design enables users to tailor their setups according to specific needs, whether it’s for small-scale operations or large, complex manufacturing lines. Furthermore, with its compatibility with GE’s extensive range of automation products, including software and hardware solutions, users can create a cohesive ecosystem that enhances overall productivity.

Usage Scenarios:

The GE FANUC is ideal for a variety of applications across industries such as automotive, food and beverage, pharmaceuticals, and energy. In automotive manufacturing, for instance, it can be employed for assembly line automation, optimizing workflows, and ensuring precision in product assembly. In the food and beverage sector, the GE FANUC is instrumental in streamlining production processes, from ingredient mixing to packaging, ensuring compliance with safety standards while maximizing output.

In pharmaceutical manufacturing, the model can manage complex batch processes, ensuring accurate measurements and strict adherence to regulatory requirements. Additionally, in energy applications, the GE FANUC can monitor and control critical systems, such as power generation and distribution, allowing for real-time adjustments to optimize supply and demand.

Comparison with Other Models:

When compared to other models within the GE automation products portfolio, such as the GE IS200TBCIH1BBC and GE IS220PPROS1B, the GE FANUC stands out for its advanced processing power and enhanced connectivity options. While the IS200 series offers reliability for specific applications, the FANUC is designed for a broader range of industries and applications, providing a more flexible solution for diverse automation needs.

Moreover, models like the GE IC697MDL250 and GE IS215UCVEH2AB focus on specialized functions, whereas the GE FANUC serves as a comprehensive solution that can integrate various functionalities into a single platform. This makes the FANUC an excellent choice for businesses looking to streamline their automation efforts without compromising on performance.

Reference to Related Models:

The versatility of the GE FANUC is complemented by its compatibility with related models such as the GE DS200CTBAG1ADD, GE IS200TPROH1BCB, GE IC660ELB912, and GE IS200EPSMG2ADC. These models provide additional capabilities, from advanced motion control (GE IS200TPROH1BCB) to enhanced communication features (GE IC660ELB912). Other notable companions in the GE automation products line include the GE IS230SNIDH1A, GE 531X307LTBAJG1, and GE IC670MDL740J, which can be utilized in tandem to create a robust, integrated automation system.

In conclusion, the GE FANUC is a powerful and adaptable solution for industries seeking to enhance their automation capabilities. With its advanced technical features, diverse usage scenarios, and compatibility with a wide range of GE automation products, the GE FANUC is positioned as a leader in industrial automation. Whether you are looking to streamline production processes or optimize complex systems, the GE FANUC delivers unparalleled performance and reliability, making it an indispensable tool in today’s competitive marketplace.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE FANUC model boasts a robust architecture that includes high-speed processing capabilities, advanced input/output modules, and extensive networking options. With its high-performance CPU, the GE FANUC processes complex algorithms swiftly, reducing downtime and enhancing operational throughput. The model supports a wide array of communication protocols, making it highly adaptable to existing systems. Additionally, the GE FANUC features comprehensive diagnostic tools that facilitate real-time monitoring and troubleshooting, ensuring that your operations run smoothly.

One of the standout features is its scalability, allowing businesses to expand their automation capabilities without overhauling existing infrastructure. The GE FANUC's modular design enables users to tailor their setups according to specific needs, whether it’s for small-scale operations or large, complex manufacturing lines. Furthermore, with its compatibility with GE’s extensive range of automation products, including software and hardware solutions, users can create a cohesive ecosystem that enhances overall productivity.

Usage Scenarios:

The GE FANUC is ideal for a variety of applications across industries such as automotive, food and beverage, pharmaceuticals, and energy. In automotive manufacturing, for instance, it can be employed for assembly line automation, optimizing workflows, and ensuring precision in product assembly. In the food and beverage sector, the GE FANUC is instrumental in streamlining production processes, from ingredient mixing to packaging, ensuring compliance with safety standards while maximizing output.

In pharmaceutical manufacturing, the model can manage complex batch processes, ensuring accurate measurements and strict adherence to regulatory requirements. Additionally, in energy applications, the GE FANUC can monitor and control critical systems, such as power generation and distribution, allowing for real-time adjustments to optimize supply and demand.

Comparison with Other Models:

When compared to other models within the GE automation products portfolio, such as the GE IS200TBCIH1BBC and GE IS220PPROS1B, the GE FANUC stands out for its advanced processing power and enhanced connectivity options. While the IS200 series offers reliability for specific applications, the FANUC is designed for a broader range of industries and applications, providing a more flexible solution for diverse automation needs.

Moreover, models like the GE IC697MDL250 and GE IS215UCVEH2AB focus on specialized functions, whereas the GE FANUC serves as a comprehensive solution that can integrate various functionalities into a single platform. This makes the FANUC an excellent choice for businesses looking to streamline their automation efforts without compromising on performance.

Reference to Related Models:

The versatility of the GE FANUC is complemented by its compatibility with related models such as the GE DS200CTBAG1ADD, GE IS200TPROH1BCB, GE IC660ELB912, and GE IS200EPSMG2ADC. These models provide additional capabilities, from advanced motion control (GE IS200TPROH1BCB) to enhanced communication features (GE IC660ELB912). Other notable companions in the GE automation products line include the GE IS230SNIDH1A, GE 531X307LTBAJG1, and GE IC670MDL740J, which can be utilized in tandem to create a robust, integrated automation system.

In conclusion, the GE FANUC is a powerful and adaptable solution for industries seeking to enhance their automation capabilities. With its advanced technical features, diverse usage scenarios, and compatibility with a wide range of GE automation products, the GE FANUC is positioned as a leader in industrial automation. Whether you are looking to streamline production processes or optimize complex systems, the GE FANUC delivers unparalleled performance and reliability, making it an indispensable tool in today’s competitive marketplace.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.