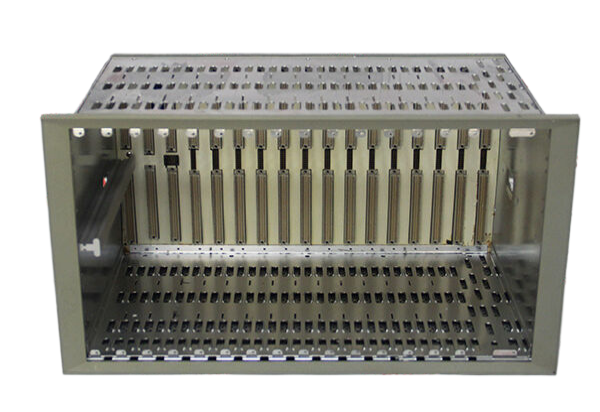

BENTLY Nevada 3500/46M 176449-06 Hydro Monitor

Introducing the BENTLY Nevada: The Pinnacle of Condition Monitoring Technology

The BENTLY Nevada series has long been synonymous with excellence in condition monitoring and machinery protection. Among its standout models, the BENTLY Nevada 3500 series is engineered to provide unparalleled reliability and performance in the most demanding industrial environments. This product is a perfect blend of advanced technology, robust design, and user-friendly features, making it a preferred choice for industries ranging from oil and gas to power generation.

Key Technical Features

The BENTLY Nevada 3500 series boasts an impressive array of technical features designed to enhance operational efficiency and extend equipment life. With its multi-channel architecture, this system can monitor a wide variety of parameters including vibration, temperature, and speed, all in real-time. The model incorporates advanced signal processing algorithms that ensure accurate data collection, enabling predictive maintenance practices that minimize downtime. Additionally, the BENTLY Nevada 3500 supports a variety of communication protocols, making it compatible with existing automation systems and facilitating seamless integration into your operations.

Another notable feature is the unit's rugged design, which enhances its durability in harsh environments. The BENTLY Nevada is built to withstand extreme temperatures, humidity, and vibration, ensuring reliable performance in challenging conditions. The intuitive user interface allows operators to access critical data quickly, simplifying the monitoring process and reducing the risk of human error.

Usage Scenarios

The BENTLY Nevada 3500 series is ideal for a myriad of applications where machinery health is critical. In the oil and gas sector, it can monitor pumps, compressors, and turbines, ensuring optimal performance and safety. In power generation, the system is invaluable for monitoring the health of turbines, generators, and other essential equipment. Additionally, the BENTLY Nevada is widely used in manufacturing plants to oversee rotating machinery, which plays a crucial role in maintaining production efficiency.

This model is also well-suited for industries such as mining, where the need for continuous monitoring of equipment is essential to prevent costly breakdowns. Its versatility ensures that wherever there is rotating machinery, the BENTLY Nevada can provide valuable insights into equipment health, allowing for timely maintenance and reduced operational costs.

Comparison with Other Models

When compared to other models within the BENTLY product line, such as the BENTLY 3500/20 or BENTLY 3500/42M, the 3500 series stands out for its advanced capabilities and comprehensive monitoring options. While the BENTLY 3500/20 focuses on basic vibration monitoring, the Nevada series integrates multiple parameters, offering a more holistic view of machinery health. Similarly, the BENTLY 3500/42M is excellent for vibration analysis, but the Nevada’s enhanced data processing capabilities make it a superior choice for predictive analytics.

Moreover, the BENTLY Nevada 3500 is built with scalability in mind, allowing it to grow alongside your operations. With the ability to expand its monitoring channels, it can adapt to meet the evolving needs of

The above parameters are for reference only. Please contact our technical team for precise selection.

The BENTLY Nevada series has long been synonymous with excellence in condition monitoring and machinery protection. Among its standout models, the BENTLY Nevada 3500 series is engineered to provide unparalleled reliability and performance in the most demanding industrial environments. This product is a perfect blend of advanced technology, robust design, and user-friendly features, making it a preferred choice for industries ranging from oil and gas to power generation.

Key Technical Features

The BENTLY Nevada 3500 series boasts an impressive array of technical features designed to enhance operational efficiency and extend equipment life. With its multi-channel architecture, this system can monitor a wide variety of parameters including vibration, temperature, and speed, all in real-time. The model incorporates advanced signal processing algorithms that ensure accurate data collection, enabling predictive maintenance practices that minimize downtime. Additionally, the BENTLY Nevada 3500 supports a variety of communication protocols, making it compatible with existing automation systems and facilitating seamless integration into your operations.

Another notable feature is the unit's rugged design, which enhances its durability in harsh environments. The BENTLY Nevada is built to withstand extreme temperatures, humidity, and vibration, ensuring reliable performance in challenging conditions. The intuitive user interface allows operators to access critical data quickly, simplifying the monitoring process and reducing the risk of human error.

Usage Scenarios

The BENTLY Nevada 3500 series is ideal for a myriad of applications where machinery health is critical. In the oil and gas sector, it can monitor pumps, compressors, and turbines, ensuring optimal performance and safety. In power generation, the system is invaluable for monitoring the health of turbines, generators, and other essential equipment. Additionally, the BENTLY Nevada is widely used in manufacturing plants to oversee rotating machinery, which plays a crucial role in maintaining production efficiency.

This model is also well-suited for industries such as mining, where the need for continuous monitoring of equipment is essential to prevent costly breakdowns. Its versatility ensures that wherever there is rotating machinery, the BENTLY Nevada can provide valuable insights into equipment health, allowing for timely maintenance and reduced operational costs.

Comparison with Other Models

When compared to other models within the BENTLY product line, such as the BENTLY 3500/20 or BENTLY 3500/42M, the 3500 series stands out for its advanced capabilities and comprehensive monitoring options. While the BENTLY 3500/20 focuses on basic vibration monitoring, the Nevada series integrates multiple parameters, offering a more holistic view of machinery health. Similarly, the BENTLY 3500/42M is excellent for vibration analysis, but the Nevada’s enhanced data processing capabilities make it a superior choice for predictive analytics.

Moreover, the BENTLY Nevada 3500 is built with scalability in mind, allowing it to grow alongside your operations. With the ability to expand its monitoring channels, it can adapt to meet the evolving needs of

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.