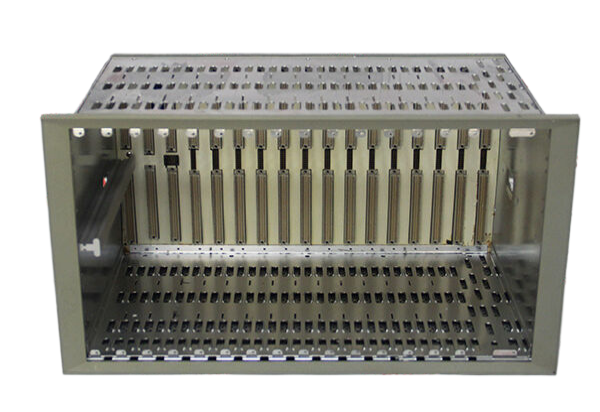

BENTLY Nevada 3500/33 184631-01F 16-Channel Relay Module

Introducing the BENTLY Nevada 3500/33 184631-01F, a cutting-edge component in BENTLY's renowned line of automation products designed for unparalleled performance in condition monitoring and machine protection. With its advanced capabilities, this model offers a comprehensive solution to enhance system reliability and operational efficiency across various industrial applications.

Key Technical Features:

The BENTLY Nevada 3500/33 184631-01F is engineered with state-of-the-art technology to provide accurate and real-time monitoring of machinery health. It features a high-resolution measurement system that captures critical data, enabling predictive maintenance strategies. The device supports a wide range of sensors, making it versatile for different machinery types and configurations. Additionally, it is equipped with advanced signal processing algorithms that filter out noise and enhance the accuracy of vibration analysis, essential for identifying potential faults before they escalate into costly failures.

One of the standout features of the BENTLY Nevada 3500/33 is its robust communication capabilities. It supports multiple protocols, including Ethernet and serial communications, allowing for seamless integration with existing systems. This model also boasts an extensive temperature range and is designed to withstand harsh industrial environments, ensuring consistent performance even under extreme conditions.

Usage Scenarios:

The BENTLY Nevada 3500/33 184631-01F is ideal for industries such as oil and gas, power generation, and manufacturing, where machinery uptime is critical. In oil and gas applications, it can be used to monitor pumps and compressors, providing insights that help prevent unplanned shutdowns. In power generation, it allows for the continuous assessment of turbines and generators, ensuring optimal performance and safety. Furthermore, in manufacturing settings, this model can be employed to monitor production equipment, enhancing operational efficiency and reducing maintenance costs.

Comparison with Other Models:

When compared to other models in the BENTLY Nevada series, such as the BENTLY 3500/20 125744-02 and BENTLY 3500/40M, the 3500/33 stands out for its superior data processing capabilities and enhanced communication options. While the BENTLY 3500/20 focuses primarily on vibration monitoring, the 3500/33 offers a more comprehensive solution by integrating various monitoring functions into a single unit. Additionally, the BENTLY 3500/40M is excellent for dynamic monitoring but may lack the same level of integration found in the 3500/33, making the latter a more flexible choice for diverse applications.

The BENTLY Nevada 3500/33 184631-01F also compares favorably against models such as the BENTLY 3500/53 and the BENTLY 3500/92, particularly in environments requiring extensive data collection and analysis. Its advanced features and adaptability make it a preferred option for facilities looking to implement robust condition monitoring solutions.

Related Models:

If you are considering the BENTLY Nevada 3500/33 184631-01F, you may

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY Nevada 3500/33 184631-01F is engineered with state-of-the-art technology to provide accurate and real-time monitoring of machinery health. It features a high-resolution measurement system that captures critical data, enabling predictive maintenance strategies. The device supports a wide range of sensors, making it versatile for different machinery types and configurations. Additionally, it is equipped with advanced signal processing algorithms that filter out noise and enhance the accuracy of vibration analysis, essential for identifying potential faults before they escalate into costly failures.

One of the standout features of the BENTLY Nevada 3500/33 is its robust communication capabilities. It supports multiple protocols, including Ethernet and serial communications, allowing for seamless integration with existing systems. This model also boasts an extensive temperature range and is designed to withstand harsh industrial environments, ensuring consistent performance even under extreme conditions.

Usage Scenarios:

The BENTLY Nevada 3500/33 184631-01F is ideal for industries such as oil and gas, power generation, and manufacturing, where machinery uptime is critical. In oil and gas applications, it can be used to monitor pumps and compressors, providing insights that help prevent unplanned shutdowns. In power generation, it allows for the continuous assessment of turbines and generators, ensuring optimal performance and safety. Furthermore, in manufacturing settings, this model can be employed to monitor production equipment, enhancing operational efficiency and reducing maintenance costs.

Comparison with Other Models:

When compared to other models in the BENTLY Nevada series, such as the BENTLY 3500/20 125744-02 and BENTLY 3500/40M, the 3500/33 stands out for its superior data processing capabilities and enhanced communication options. While the BENTLY 3500/20 focuses primarily on vibration monitoring, the 3500/33 offers a more comprehensive solution by integrating various monitoring functions into a single unit. Additionally, the BENTLY 3500/40M is excellent for dynamic monitoring but may lack the same level of integration found in the 3500/33, making the latter a more flexible choice for diverse applications.

The BENTLY Nevada 3500/33 184631-01F also compares favorably against models such as the BENTLY 3500/53 and the BENTLY 3500/92, particularly in environments requiring extensive data collection and analysis. Its advanced features and adaptability make it a preferred option for facilities looking to implement robust condition monitoring solutions.

Related Models:

If you are considering the BENTLY Nevada 3500/33 184631-01F, you may

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.