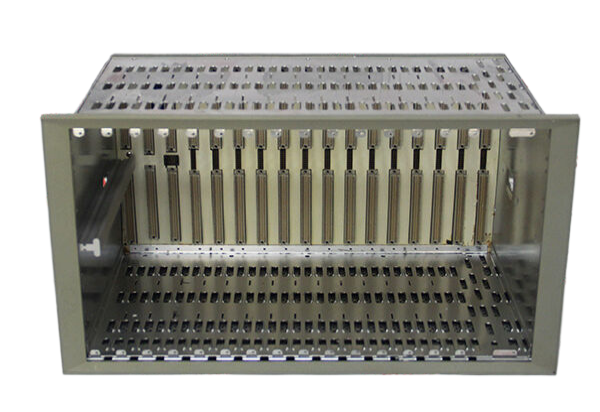

BENTLY Nevada 330173-00-07-10-02-00 Precision Proximity Probes for Industrial Control Systems

Introducing the BENTLY Nevada 330173-00-07-10-02-00 – a pinnacle of reliability and precision in condition monitoring and predictive maintenance technology. This advanced model from BENTLY’s renowned automation products line is engineered to enhance operational efficiency, minimize downtime, and protect critical assets across various industries.

Key Technical Features:

The BENTLY Nevada 330173-00-07-10-02-00 boasts an extensive array of features designed for superior performance and functionality. Equipped with cutting-edge sensors, this model captures real-time data on vibrations, temperature, and other critical parameters, providing actionable insights that help predict equipment failures before they occur. Its robust design ensures durability in harsh environments, while its compatibility with various BENTLY automation products streamlines integration into existing systems.

The BENTLY Nevada model operates with high precision, thanks to its advanced signal processing algorithms, which filter out noise and enhance data clarity. Its user-friendly interface allows for easy configuration, making it accessible for operators and technicians alike. Additionally, the model supports remote monitoring capabilities, enabling users to stay informed about equipment status from anywhere, thus facilitating proactive maintenance strategies.

Usage Scenarios:

The BENTLY Nevada 330173-00-07-10-02-00 is ideal for a multitude of applications across different sectors, including oil and gas, power generation, manufacturing, and water treatment. In oil and gas facilities, this model can monitor rotating machinery, ensuring that pumps, compressors, and turbines operate efficiently and without unexpected failures. In power generation, it safeguards critical components such as generators and turbines, enhancing overall plant reliability.

Manufacturers can leverage the BENTLY Nevada 330173-00-07-10-02-00 to monitor conveyor belts, milling machines, and other equipment, ensuring they run smoothly and maintain high productivity levels. In the water treatment sector, this model helps monitor pumps and motors, ensuring compliance with regulatory standards while optimizing performance.

Comparison with Other Models:

When compared to other BENTLY models such as the 3500/20 125744-02 or the 3500/45 176449-04, the BENTLY Nevada 330173-00-07-10-02-00 stands out due to its enhanced feature set tailored for a wider range of applications. While models like the BENTLY 3500 series focus primarily on specific machinery, the 330173-00-07-10-02-00 offers versatility in monitoring various types of equipment.

Additionally, the BENTLY 330500-00-00 and the 3500/40M 176449-01 are designed for specific applications, but the 330173-00-07-10-02-00 combines broader functionality with advanced analytics capabilities, making it a more comprehensive solution for those needing cost-effective predictive maintenance.

Related Models:

For those exploring options within the BENTLY automation products range, several related models might be of interest. The

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY Nevada 330173-00-07-10-02-00 boasts an extensive array of features designed for superior performance and functionality. Equipped with cutting-edge sensors, this model captures real-time data on vibrations, temperature, and other critical parameters, providing actionable insights that help predict equipment failures before they occur. Its robust design ensures durability in harsh environments, while its compatibility with various BENTLY automation products streamlines integration into existing systems.

The BENTLY Nevada model operates with high precision, thanks to its advanced signal processing algorithms, which filter out noise and enhance data clarity. Its user-friendly interface allows for easy configuration, making it accessible for operators and technicians alike. Additionally, the model supports remote monitoring capabilities, enabling users to stay informed about equipment status from anywhere, thus facilitating proactive maintenance strategies.

Usage Scenarios:

The BENTLY Nevada 330173-00-07-10-02-00 is ideal for a multitude of applications across different sectors, including oil and gas, power generation, manufacturing, and water treatment. In oil and gas facilities, this model can monitor rotating machinery, ensuring that pumps, compressors, and turbines operate efficiently and without unexpected failures. In power generation, it safeguards critical components such as generators and turbines, enhancing overall plant reliability.

Manufacturers can leverage the BENTLY Nevada 330173-00-07-10-02-00 to monitor conveyor belts, milling machines, and other equipment, ensuring they run smoothly and maintain high productivity levels. In the water treatment sector, this model helps monitor pumps and motors, ensuring compliance with regulatory standards while optimizing performance.

Comparison with Other Models:

When compared to other BENTLY models such as the 3500/20 125744-02 or the 3500/45 176449-04, the BENTLY Nevada 330173-00-07-10-02-00 stands out due to its enhanced feature set tailored for a wider range of applications. While models like the BENTLY 3500 series focus primarily on specific machinery, the 330173-00-07-10-02-00 offers versatility in monitoring various types of equipment.

Additionally, the BENTLY 330500-00-00 and the 3500/40M 176449-01 are designed for specific applications, but the 330173-00-07-10-02-00 combines broader functionality with advanced analytics capabilities, making it a more comprehensive solution for those needing cost-effective predictive maintenance.

Related Models:

For those exploring options within the BENTLY automation products range, several related models might be of interest. The

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.