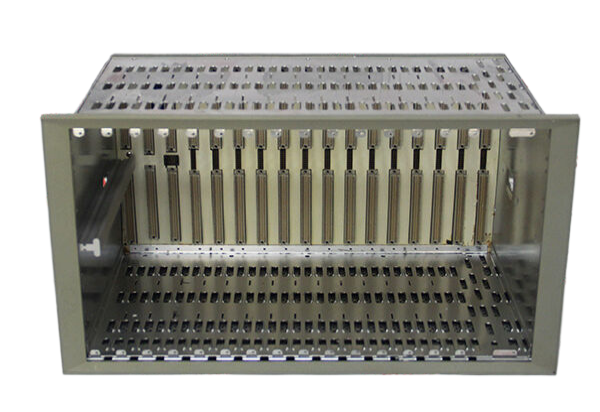

BENTLY Nevada 330130-045-01-00 Extension Cable for Industrial Control Systems

Introducing the BENTLY Nevada: The Pinnacle of Condition Monitoring and Control

In the world of industrial automation, precision and reliability are paramount. The BENTLY Nevada model stands out as a premier solution for condition monitoring and control, designed to optimize performance and safety across various applications. This state-of-the-art product integrates advanced technology with user-friendly features, making it an essential tool for industries ranging from manufacturing to energy production.

Key Technical Features

The BENTLY Nevada is engineered with cutting-edge technology, ensuring accurate and real-time monitoring of machinery and critical systems. Key features include:

1. **High-Resolution Sensors**: The model utilizes high-resolution vibration sensors, capable of detecting even the slightest variations in machinery performance, which is crucial for predictive maintenance.

2. **Robust Data Acquisition**: With its sophisticated data acquisition capabilities, the BENTLY Nevada can collect and analyze data on vibration, temperature, and other parameters, providing comprehensive insights into equipment health.

3. **Modular Design**: The modular architecture allows for easy scalability and customization. Users can tailor the system to meet their specific needs, integrating seamlessly with other BENTLY automation products.

4. **User-Friendly Interface**: The intuitive interface simplifies operation, enabling users to access critical information quickly and efficiently. This reduces the learning curve and accelerates deployment.

5. **Remote Monitoring**: Featuring advanced communication protocols, the BENTLY Nevada supports remote monitoring capabilities, allowing operators to oversee machinery from anywhere, thus enhancing operational flexibility.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for a broad range of applications. In power generation, it monitors turbine performance, ensuring optimal efficiency and safety. In manufacturing, it oversees critical machinery, enabling predictive maintenance that reduces downtime and extends equipment lifespan. Additionally, in oil and gas operations, the BENTLY Nevada is vital for monitoring pumps and compressors, safeguarding against costly failures and environmental hazards.

Comparison with Other Models

When compared to other models within the BENTLY lineup, such as the BENTLY 3500/20 and BENTLY 3500/50, the BENTLY Nevada distinguishes itself through its enhanced data acquisition and modular capabilities. While the BENTLY 3500/20 is tailored for more straightforward applications, the BENTLY Nevada's advanced features cater to complex industrial environments requiring robust condition monitoring. Similarly, compared to the BENTLY 3500/40M, which offers excellent performance, the BENTLY Nevada provides superior remote monitoring options and a more user-centric interface, making it the preferred choice for many operators.

Related Models

For those exploring the extensive BENTLY automation products, consider these related models that complement the BENTLY Nevada:

1. BENTLY 3500/20 125744-02

2. BENTLY 3500/45 176449-04

3. BENTLY 3500/34

4. BENTLY 3500

The above parameters are for reference only. Please contact our technical team for precise selection.

In the world of industrial automation, precision and reliability are paramount. The BENTLY Nevada model stands out as a premier solution for condition monitoring and control, designed to optimize performance and safety across various applications. This state-of-the-art product integrates advanced technology with user-friendly features, making it an essential tool for industries ranging from manufacturing to energy production.

Key Technical Features

The BENTLY Nevada is engineered with cutting-edge technology, ensuring accurate and real-time monitoring of machinery and critical systems. Key features include:

1. **High-Resolution Sensors**: The model utilizes high-resolution vibration sensors, capable of detecting even the slightest variations in machinery performance, which is crucial for predictive maintenance.

2. **Robust Data Acquisition**: With its sophisticated data acquisition capabilities, the BENTLY Nevada can collect and analyze data on vibration, temperature, and other parameters, providing comprehensive insights into equipment health.

3. **Modular Design**: The modular architecture allows for easy scalability and customization. Users can tailor the system to meet their specific needs, integrating seamlessly with other BENTLY automation products.

4. **User-Friendly Interface**: The intuitive interface simplifies operation, enabling users to access critical information quickly and efficiently. This reduces the learning curve and accelerates deployment.

5. **Remote Monitoring**: Featuring advanced communication protocols, the BENTLY Nevada supports remote monitoring capabilities, allowing operators to oversee machinery from anywhere, thus enhancing operational flexibility.

Usage Scenarios

The versatility of the BENTLY Nevada makes it suitable for a broad range of applications. In power generation, it monitors turbine performance, ensuring optimal efficiency and safety. In manufacturing, it oversees critical machinery, enabling predictive maintenance that reduces downtime and extends equipment lifespan. Additionally, in oil and gas operations, the BENTLY Nevada is vital for monitoring pumps and compressors, safeguarding against costly failures and environmental hazards.

Comparison with Other Models

When compared to other models within the BENTLY lineup, such as the BENTLY 3500/20 and BENTLY 3500/50, the BENTLY Nevada distinguishes itself through its enhanced data acquisition and modular capabilities. While the BENTLY 3500/20 is tailored for more straightforward applications, the BENTLY Nevada's advanced features cater to complex industrial environments requiring robust condition monitoring. Similarly, compared to the BENTLY 3500/40M, which offers excellent performance, the BENTLY Nevada provides superior remote monitoring options and a more user-centric interface, making it the preferred choice for many operators.

Related Models

For those exploring the extensive BENTLY automation products, consider these related models that complement the BENTLY Nevada:

1. BENTLY 3500/20 125744-02

2. BENTLY 3500/45 176449-04

3. BENTLY 3500/34

4. BENTLY 3500

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.