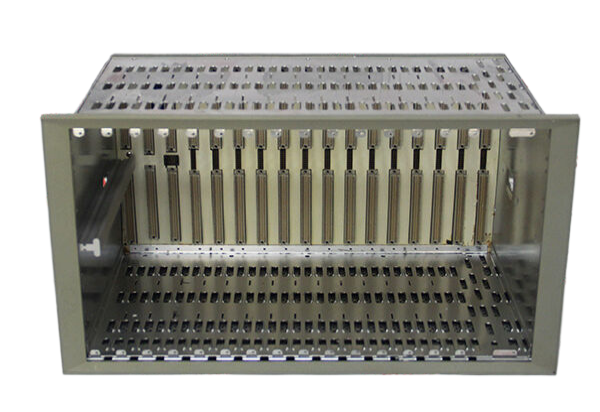

BENTLY Nevada 330130-040-10-CN | 3300 XL Series | Extension Cable

Introducing the BENTLY Nevada, a cutting-edge solution in the realm of industrial monitoring and diagnostics. Designed for reliability and precision, the BENTLY Nevada series exemplifies excellence in condition monitoring technology, making it an essential tool for industries ranging from energy to manufacturing.

Key Technical Features:

The BENTLY Nevada is engineered with a robust set of features that ensure optimal performance. It boasts high-speed data acquisition, enabling real-time monitoring of critical parameters such as vibration, temperature, and pressure. With its advanced algorithms and signal processing capabilities, the BENTLY Nevada can detect anomalies early, allowing for predictive maintenance and minimizing unplanned downtime. The system supports multiple input channels, which can be customized to meet specific operational needs. Its compatibility with various sensors enhances its versatility, making it a go-to choice for diverse applications. The BENTLY Nevada also features seamless integration with existing systems, ensuring that data can be easily accessed and analyzed.

Usage Scenarios:

The BENTLY Nevada shines in numerous usage scenarios. In the energy sector, it is employed to monitor the health of turbines and generators, providing crucial insights that help prevent catastrophic failures. Manufacturing plants utilize the BENTLY Nevada for machinery condition monitoring, allowing operators to identify wear and tear before it escalates into costly breakdowns. In the oil and gas industry, this model is pivotal for ensuring the integrity of equipment in challenging environments, where failure can lead to significant operational disruptions. Additionally, the BENTLY Nevada is frequently used in water treatment facilities, where precise monitoring is essential for maintaining system efficiency.

Comparison with Other Models:

When compared to other models within the BENTLY lineup, such as the BENTLY 3500/20 and BENTLY 3500/40M, the BENTLY Nevada stands out for its enhanced data processing capabilities and flexibility in configuration. While models like the BENTLY 3500/50 and BENTLY 3500/92 offer robust monitoring solutions, the Nevada's superior adaptability allows it to cater to a broader range of applications. The BENTLY 3500/53 and BENTLY 3500/42M are excellent for specific monitoring tasks, but the BENTLY Nevada’s comprehensive approach to condition monitoring makes it an invaluable asset for any industrial operation.

Related Models:

The BENTLY Nevada is part of an extensive family of BENTLY automation products designed to foster operational efficiency. Key related models include the BENTLY 3500/20 (125744-02), known for its reliable vibration monitoring; the BENTLY 3500/45 (176449-04), which excels in temperature monitoring; and the BENTLY 330500-00-00, a versatile choice for various applications. The BENTLY 131151-01 provides excellent integration capabilities, while the BENTLY 3500/53 (133388-01) is tailored for advanced diagnostics. Additionally, the BENTLY 3500

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY Nevada is engineered with a robust set of features that ensure optimal performance. It boasts high-speed data acquisition, enabling real-time monitoring of critical parameters such as vibration, temperature, and pressure. With its advanced algorithms and signal processing capabilities, the BENTLY Nevada can detect anomalies early, allowing for predictive maintenance and minimizing unplanned downtime. The system supports multiple input channels, which can be customized to meet specific operational needs. Its compatibility with various sensors enhances its versatility, making it a go-to choice for diverse applications. The BENTLY Nevada also features seamless integration with existing systems, ensuring that data can be easily accessed and analyzed.

Usage Scenarios:

The BENTLY Nevada shines in numerous usage scenarios. In the energy sector, it is employed to monitor the health of turbines and generators, providing crucial insights that help prevent catastrophic failures. Manufacturing plants utilize the BENTLY Nevada for machinery condition monitoring, allowing operators to identify wear and tear before it escalates into costly breakdowns. In the oil and gas industry, this model is pivotal for ensuring the integrity of equipment in challenging environments, where failure can lead to significant operational disruptions. Additionally, the BENTLY Nevada is frequently used in water treatment facilities, where precise monitoring is essential for maintaining system efficiency.

Comparison with Other Models:

When compared to other models within the BENTLY lineup, such as the BENTLY 3500/20 and BENTLY 3500/40M, the BENTLY Nevada stands out for its enhanced data processing capabilities and flexibility in configuration. While models like the BENTLY 3500/50 and BENTLY 3500/92 offer robust monitoring solutions, the Nevada's superior adaptability allows it to cater to a broader range of applications. The BENTLY 3500/53 and BENTLY 3500/42M are excellent for specific monitoring tasks, but the BENTLY Nevada’s comprehensive approach to condition monitoring makes it an invaluable asset for any industrial operation.

Related Models:

The BENTLY Nevada is part of an extensive family of BENTLY automation products designed to foster operational efficiency. Key related models include the BENTLY 3500/20 (125744-02), known for its reliable vibration monitoring; the BENTLY 3500/45 (176449-04), which excels in temperature monitoring; and the BENTLY 330500-00-00, a versatile choice for various applications. The BENTLY 131151-01 provides excellent integration capabilities, while the BENTLY 3500/53 (133388-01) is tailored for advanced diagnostics. Additionally, the BENTLY 3500

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.