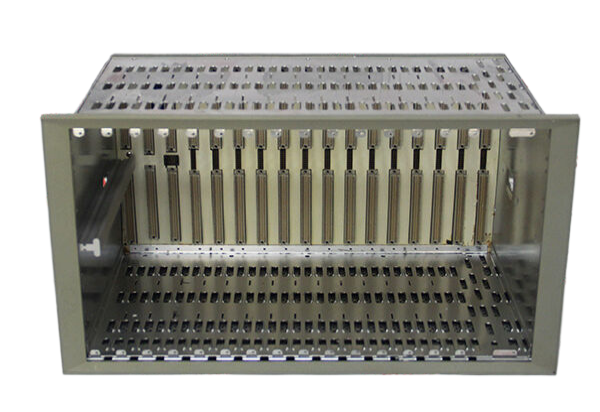

BENTLY Nevada 330104-00-04-10-02-CN Proximity Probe, Precision Measurement for Industrial Control Systems

Introducing the BENTLY Nevada – the pinnacle of reliability and performance in industrial monitoring. Renowned for its advanced technology and precision, the BENTLY Nevada sets the standard in predictive maintenance and machinery health monitoring. As part of the BENTLY automation products line, this model is designed to cater to a wide array of applications, ensuring your operations run smoothly and efficiently.

Key Technical Features:

The BENTLY Nevada boasts an impressive array of features that make it the ideal choice for demanding industrial environments. With its high-fidelity data acquisition capabilities, this model supports a comprehensive range of sensors, allowing for real-time monitoring of vibration, temperature, and other critical parameters. The system is equipped with advanced diagnostics that can identify potential issues before they escalate, significantly reducing downtime and maintenance costs.

One of the standout features of the BENTLY Nevada is its robust communication protocols, ensuring seamless integration with existing systems and facilitating the transfer of data to centralized monitoring systems. Its flexibility allows users to customize configurations according to their specific needs, making it suitable for various applications in industries such as oil and gas, power generation, and manufacturing.

Usage Scenarios:

The BENTLY Nevada is designed for a multitude of applications across diverse sectors. In power generation facilities, it monitors turbine performance, ensuring optimal efficiency and reliability. In the oil and gas industry, it tracks the condition of pumps and compressors, helping to prevent failures that can lead to costly shutdowns. Manufacturing plants benefit from its ability to monitor machinery, ensuring that production lines operate without interruption.

In addition to these applications, the BENTLY Nevada system is also ideal for retrofitting older machinery, providing a cost-effective solution for upgrading monitoring capabilities without replacing entire systems. Whether it's in a bustling factory or a remote oil field, the BENTLY Nevada ensures that your operations are continuously monitored and optimized.

Comparison with Other Models:

When compared to other models in the BENTLY lineup, such as the BENTLY 3500/20 and BENTLY 3500/50, the Nevada offers enhanced features that cater specifically to complex monitoring needs. While the BENTLY 3500 series provides solid performance for basic monitoring tasks, the Nevada excels in environments requiring advanced predictive analytics and real-time data processing.

For instance, the BENTLY 3500/42M and BENTLY 3500/53 models are great for specific applications; however, the BENTLY Nevada's comprehensive monitoring capabilities and adaptability make it a more versatile option for organizations looking to invest in long-term maintenance solutions.

Related Models:

For those exploring the BENTLY automation products family, several models complement the BENTLY Nevada. The BENTLY 3500/20 (125744-02) provides reliable vibration monitoring, while the BENTLY 3500/45 (176449-04) is designed for advanced control applications. The BENTLY 60M100-00 is another option for users seeking high-performance machinery monitoring.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY Nevada boasts an impressive array of features that make it the ideal choice for demanding industrial environments. With its high-fidelity data acquisition capabilities, this model supports a comprehensive range of sensors, allowing for real-time monitoring of vibration, temperature, and other critical parameters. The system is equipped with advanced diagnostics that can identify potential issues before they escalate, significantly reducing downtime and maintenance costs.

One of the standout features of the BENTLY Nevada is its robust communication protocols, ensuring seamless integration with existing systems and facilitating the transfer of data to centralized monitoring systems. Its flexibility allows users to customize configurations according to their specific needs, making it suitable for various applications in industries such as oil and gas, power generation, and manufacturing.

Usage Scenarios:

The BENTLY Nevada is designed for a multitude of applications across diverse sectors. In power generation facilities, it monitors turbine performance, ensuring optimal efficiency and reliability. In the oil and gas industry, it tracks the condition of pumps and compressors, helping to prevent failures that can lead to costly shutdowns. Manufacturing plants benefit from its ability to monitor machinery, ensuring that production lines operate without interruption.

In addition to these applications, the BENTLY Nevada system is also ideal for retrofitting older machinery, providing a cost-effective solution for upgrading monitoring capabilities without replacing entire systems. Whether it's in a bustling factory or a remote oil field, the BENTLY Nevada ensures that your operations are continuously monitored and optimized.

Comparison with Other Models:

When compared to other models in the BENTLY lineup, such as the BENTLY 3500/20 and BENTLY 3500/50, the Nevada offers enhanced features that cater specifically to complex monitoring needs. While the BENTLY 3500 series provides solid performance for basic monitoring tasks, the Nevada excels in environments requiring advanced predictive analytics and real-time data processing.

For instance, the BENTLY 3500/42M and BENTLY 3500/53 models are great for specific applications; however, the BENTLY Nevada's comprehensive monitoring capabilities and adaptability make it a more versatile option for organizations looking to invest in long-term maintenance solutions.

Related Models:

For those exploring the BENTLY automation products family, several models complement the BENTLY Nevada. The BENTLY 3500/20 (125744-02) provides reliable vibration monitoring, while the BENTLY 3500/45 (176449-04) is designed for advanced control applications. The BENTLY 60M100-00 is another option for users seeking high-performance machinery monitoring.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.