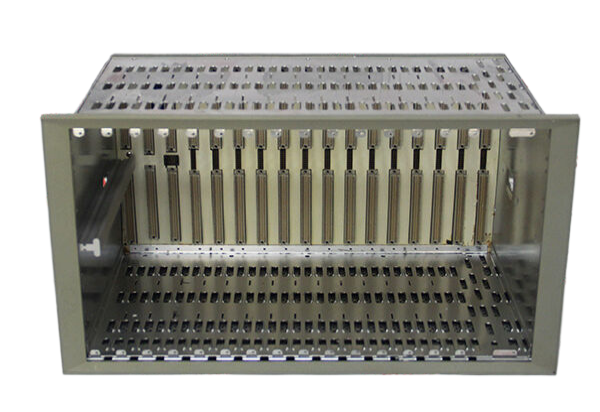

BENTLY Nevada 3300/65-14-01-00-01-00 Precision Dual Vibration Monitor

Introducing the BENTLY Nevada 3300/65-14-01-00-01-00: the pinnacle of precision and reliability in industrial monitoring. This advanced vibration monitoring system is expertly engineered to enhance the performance and longevity of your machinery, making it an indispensable asset for industries that demand the utmost in operational excellence.

Key Technical Features

The BENTLY Nevada 3300/65-14-01-00-01-00 offers a host of cutting-edge features that set it apart from its competitors. This model is equipped with a sophisticated sensor system designed to accurately measure vibration levels across a variety of machinery types. With its high-resolution data acquisition capabilities, the 3300/65 provides real-time monitoring of critical parameters, ensuring that any anomalies are detected early, mitigating the risk of failure.

This model supports a wide frequency range and features a robust design that withstands harsh industrial environments. The BENTLY Nevada 3300/65-14-01-00-01-00 is compatible with various BENTLY automation products, allowing for seamless integration into existing systems. With a user-friendly interface and advanced diagnostic tools, users can easily interpret data and make informed decisions to optimize machine performance.

Usage Scenarios

The BENTLY Nevada 3300/65-14-01-00-01-00 is ideal for a myriad of applications across different sectors, including manufacturing, power generation, and oil and gas. Whether you are monitoring turbines, compressors, or pumps, this model provides unparalleled insights into machine health. Its reliable performance under high-stress conditions makes it particularly suited for critical applications where downtime can lead to significant financial losses.

Facilities that prioritize preventative maintenance will benefit greatly from the BENTLY Nevada 3300/65, as it enables proactive monitoring and troubleshooting. By identifying potential failures before they occur, businesses can schedule maintenance during planned downtimes, increasing operational efficiency and reducing costs.

Comparison with Other Models

When compared to other models within the BENTLY lineup, such as the BENTLY 3500/20 125744-02 and the BENTLY 131151-01, the 3300/65 stands out for its specialized vibration monitoring capabilities. While the BENTLY 3500 series offers broader monitoring options, including temperature and pressure, the 3300/65 is specifically tailored for precision vibration analysis, making it the go-to choice for applications where vibration is a primary concern.

Additionally, models like the BENTLY 3500/42M and BENTLY 3500/50 provide different configurations suited for various monitoring needs, but they may lack the specialized features of the 3300/65. The advanced analytics and diagnostics available in the BENTLY Nevada 3300/65-14-01-00-01-00 ensure that users receive the most relevant data for vibration concerns, making it an exceptional tool for performance optimization.

Related Models

For a comprehensive understanding of the BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY Nevada 3300/65-14-01-00-01-00 offers a host of cutting-edge features that set it apart from its competitors. This model is equipped with a sophisticated sensor system designed to accurately measure vibration levels across a variety of machinery types. With its high-resolution data acquisition capabilities, the 3300/65 provides real-time monitoring of critical parameters, ensuring that any anomalies are detected early, mitigating the risk of failure.

This model supports a wide frequency range and features a robust design that withstands harsh industrial environments. The BENTLY Nevada 3300/65-14-01-00-01-00 is compatible with various BENTLY automation products, allowing for seamless integration into existing systems. With a user-friendly interface and advanced diagnostic tools, users can easily interpret data and make informed decisions to optimize machine performance.

Usage Scenarios

The BENTLY Nevada 3300/65-14-01-00-01-00 is ideal for a myriad of applications across different sectors, including manufacturing, power generation, and oil and gas. Whether you are monitoring turbines, compressors, or pumps, this model provides unparalleled insights into machine health. Its reliable performance under high-stress conditions makes it particularly suited for critical applications where downtime can lead to significant financial losses.

Facilities that prioritize preventative maintenance will benefit greatly from the BENTLY Nevada 3300/65, as it enables proactive monitoring and troubleshooting. By identifying potential failures before they occur, businesses can schedule maintenance during planned downtimes, increasing operational efficiency and reducing costs.

Comparison with Other Models

When compared to other models within the BENTLY lineup, such as the BENTLY 3500/20 125744-02 and the BENTLY 131151-01, the 3300/65 stands out for its specialized vibration monitoring capabilities. While the BENTLY 3500 series offers broader monitoring options, including temperature and pressure, the 3300/65 is specifically tailored for precision vibration analysis, making it the go-to choice for applications where vibration is a primary concern.

Additionally, models like the BENTLY 3500/42M and BENTLY 3500/50 provide different configurations suited for various monitoring needs, but they may lack the specialized features of the 3300/65. The advanced analytics and diagnostics available in the BENTLY Nevada 3300/65-14-01-00-01-00 ensure that users receive the most relevant data for vibration concerns, making it an exceptional tool for performance optimization.

Related Models

For a comprehensive understanding of the BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.