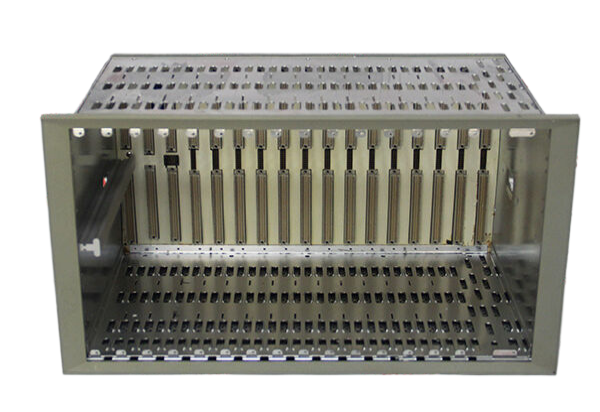

BENTLY Nevada 3300/39-03-00 Brand New Control Module

Introducing the BENTLY Nevada, a pinnacle of reliability and precision in condition monitoring and machine protection. Renowned for its advanced technology and robust design, the BENTLY Nevada is an essential tool for industries that demand uninterrupted performance and proactive maintenance.

Key Technical Features:

The BENTLY Nevada is equipped with cutting-edge features that set it apart from other models in the BENTLY lineup. It utilizes state-of-the-art sensors and data acquisition systems to monitor critical machinery parameters in real-time, ensuring optimal performance. The device boasts high-resolution data capture and advanced analytical capabilities, allowing for accurate diagnostics and predictive maintenance. Its modular architecture allows for easy expansion and integration with other BENTLY automation products, offering flexibility to meet specific operational needs. The device is also designed to withstand harsh industrial environments, featuring robust housing and superior vibration resistance.

Usage Scenarios:

Ideal for a variety of industries, the BENTLY Nevada excels in applications such as oil and gas, power generation, manufacturing, and water treatment. In oil and gas, it monitors rotating equipment like pumps and compressors, enabling early detection of anomalies that could lead to costly downtime. In power generation, it ensures the reliability of turbines and generators, providing essential data for maintenance scheduling. Manufacturing facilities benefit from the BENTLY Nevada's ability to monitor machinery health, helping to minimize unexpected failures and optimize production efficiency. In water treatment plants, it enhances the reliability of critical systems, safeguarding against operational interruptions.

Comparison with Other Models:

When compared to other models in the BENTLY family, such as the BENTLY 3500/20 and BENTLY 3500/45, the BENTLY Nevada stands out with its advanced diagnostic capabilities and real-time monitoring features. While the BENTLY 3500/20 is excellent for basic vibration monitoring, the BENTLY Nevada offers a more comprehensive solution with its ability to analyze multiple parameters simultaneously. The BENTLY 3500/45, known for its extensive analytics, lacks the rugged design and modularity of the BENTLY Nevada, making the latter a better choice for environments where reliability is paramount.

Related Models:

The BENTLY Nevada is part of a broader ecosystem of reliable monitoring solutions. Other notable models include the BENTLY 3500/50, which excels in dynamic monitoring, and the BENTLY 3300/20-12-01, known for its precision in measuring vibration levels. The BENTLY 3500/42M is another relevant model, providing comprehensive machinery protection. For those requiring enhanced diagnostics, the BENTLY 3500/53 offers advanced features that complement the BENTLY Nevada. Other models like the BENTLY 3500/25 and BENTLY 3500/40M are also part of this ecosystem, each designed to cater to specific monitoring needs while ensuring seamless integration.

In conclusion, the BENTLY Nevada is a powerful tool for industries seeking to enhance operational reliability and efficiency through advanced

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY Nevada is equipped with cutting-edge features that set it apart from other models in the BENTLY lineup. It utilizes state-of-the-art sensors and data acquisition systems to monitor critical machinery parameters in real-time, ensuring optimal performance. The device boasts high-resolution data capture and advanced analytical capabilities, allowing for accurate diagnostics and predictive maintenance. Its modular architecture allows for easy expansion and integration with other BENTLY automation products, offering flexibility to meet specific operational needs. The device is also designed to withstand harsh industrial environments, featuring robust housing and superior vibration resistance.

Usage Scenarios:

Ideal for a variety of industries, the BENTLY Nevada excels in applications such as oil and gas, power generation, manufacturing, and water treatment. In oil and gas, it monitors rotating equipment like pumps and compressors, enabling early detection of anomalies that could lead to costly downtime. In power generation, it ensures the reliability of turbines and generators, providing essential data for maintenance scheduling. Manufacturing facilities benefit from the BENTLY Nevada's ability to monitor machinery health, helping to minimize unexpected failures and optimize production efficiency. In water treatment plants, it enhances the reliability of critical systems, safeguarding against operational interruptions.

Comparison with Other Models:

When compared to other models in the BENTLY family, such as the BENTLY 3500/20 and BENTLY 3500/45, the BENTLY Nevada stands out with its advanced diagnostic capabilities and real-time monitoring features. While the BENTLY 3500/20 is excellent for basic vibration monitoring, the BENTLY Nevada offers a more comprehensive solution with its ability to analyze multiple parameters simultaneously. The BENTLY 3500/45, known for its extensive analytics, lacks the rugged design and modularity of the BENTLY Nevada, making the latter a better choice for environments where reliability is paramount.

Related Models:

The BENTLY Nevada is part of a broader ecosystem of reliable monitoring solutions. Other notable models include the BENTLY 3500/50, which excels in dynamic monitoring, and the BENTLY 3300/20-12-01, known for its precision in measuring vibration levels. The BENTLY 3500/42M is another relevant model, providing comprehensive machinery protection. For those requiring enhanced diagnostics, the BENTLY 3500/53 offers advanced features that complement the BENTLY Nevada. Other models like the BENTLY 3500/25 and BENTLY 3500/40M are also part of this ecosystem, each designed to cater to specific monitoring needs while ensuring seamless integration.

In conclusion, the BENTLY Nevada is a powerful tool for industries seeking to enhance operational reliability and efficiency through advanced

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.