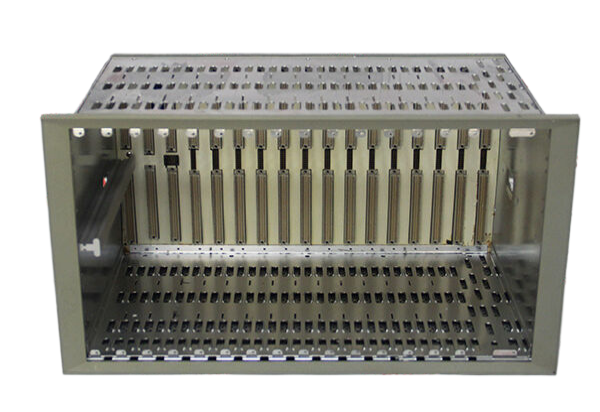

BENTLY Nevada 16710-33 Annual Discount on Advanced Automation Module

Introducing the BENTLY Nevada 16710-33, a premier solution in the realm of industrial monitoring and automation. This cutting-edge device is specifically engineered to enhance the efficiency and reliability of your operations, making it a vital addition to any facility seeking to optimize performance and minimize downtime.

Key Technical Features:

The BENTLY Nevada 16710-33 boasts an array of advanced features designed to meet the demanding needs of today’s industrial environments. It is equipped with high-resolution analog inputs, providing precise measurements of vibration and temperature, which are critical for predictive maintenance strategies. The device supports a wide range of sensors and can integrate seamlessly with existing BENTLY automation products, ensuring compatibility and ease of use. Its robust construction guarantees durability in harsh conditions, while the user-friendly interface simplifies setup and operation. Additionally, the 16710-33's built-in diagnostic capabilities offer real-time data analysis, empowering your team with actionable insights for informed decision-making.

Usage Scenarios:

The BENTLY Nevada 16710-33 is versatile and can be employed across various industrial sectors, including oil and gas, power generation, and manufacturing. It is particularly effective in monitoring rotating machinery, such as turbines, compressors, and pumps, where vibration analysis is critical for maintaining operational integrity. Users can leverage the 16710-33 for condition monitoring programs, ensuring that any potential issues are identified before they escalate into costly failures. This proactive approach not only enhances safety but also extends the lifespan of your equipment, ultimately contributing to significant cost savings.

Comparison with Other Models:

When compared to other models within the BENTLY Nevada series, such as the BENTLY 3500/20 125744-02 and the BENTLY 3500/40M, the 16710-33 stands out with its superior data acquisition capabilities and enhanced processing power. While models like the BENTLY 3500/42M focus primarily on vibration monitoring, the 16710-33 integrates temperature and additional parameters, providing a more holistic view of machine health. This makes it an ideal choice for facilities that require comprehensive monitoring solutions. Additionally, its advanced diagnostics set it apart from models such as the BENTLY 3500/15 and BENTLY 3500/25, which may not offer the same level of data granularity or analysis capabilities.

Related Models:

For facilities looking to build a comprehensive monitoring system, the BENTLY Nevada 16710-33 can be paired with a variety of related models, including the BENTLY 3500/34, BENTLY 3500/45 176449-04, BENTLY 3500/50, and BENTLY 3500/22M. Each of these models complements the 16710-33 by enhancing specific monitoring capabilities, such as temperature sensing or additional vibration analysis. Other notable mentions include the BENTLY 3300/16-11-01-03-00-00-01,

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY Nevada 16710-33 boasts an array of advanced features designed to meet the demanding needs of today’s industrial environments. It is equipped with high-resolution analog inputs, providing precise measurements of vibration and temperature, which are critical for predictive maintenance strategies. The device supports a wide range of sensors and can integrate seamlessly with existing BENTLY automation products, ensuring compatibility and ease of use. Its robust construction guarantees durability in harsh conditions, while the user-friendly interface simplifies setup and operation. Additionally, the 16710-33's built-in diagnostic capabilities offer real-time data analysis, empowering your team with actionable insights for informed decision-making.

Usage Scenarios:

The BENTLY Nevada 16710-33 is versatile and can be employed across various industrial sectors, including oil and gas, power generation, and manufacturing. It is particularly effective in monitoring rotating machinery, such as turbines, compressors, and pumps, where vibration analysis is critical for maintaining operational integrity. Users can leverage the 16710-33 for condition monitoring programs, ensuring that any potential issues are identified before they escalate into costly failures. This proactive approach not only enhances safety but also extends the lifespan of your equipment, ultimately contributing to significant cost savings.

Comparison with Other Models:

When compared to other models within the BENTLY Nevada series, such as the BENTLY 3500/20 125744-02 and the BENTLY 3500/40M, the 16710-33 stands out with its superior data acquisition capabilities and enhanced processing power. While models like the BENTLY 3500/42M focus primarily on vibration monitoring, the 16710-33 integrates temperature and additional parameters, providing a more holistic view of machine health. This makes it an ideal choice for facilities that require comprehensive monitoring solutions. Additionally, its advanced diagnostics set it apart from models such as the BENTLY 3500/15 and BENTLY 3500/25, which may not offer the same level of data granularity or analysis capabilities.

Related Models:

For facilities looking to build a comprehensive monitoring system, the BENTLY Nevada 16710-33 can be paired with a variety of related models, including the BENTLY 3500/34, BENTLY 3500/45 176449-04, BENTLY 3500/50, and BENTLY 3500/22M. Each of these models complements the 16710-33 by enhancing specific monitoring capabilities, such as temperature sensing or additional vibration analysis. Other notable mentions include the BENTLY 3300/16-11-01-03-00-00-01,

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.