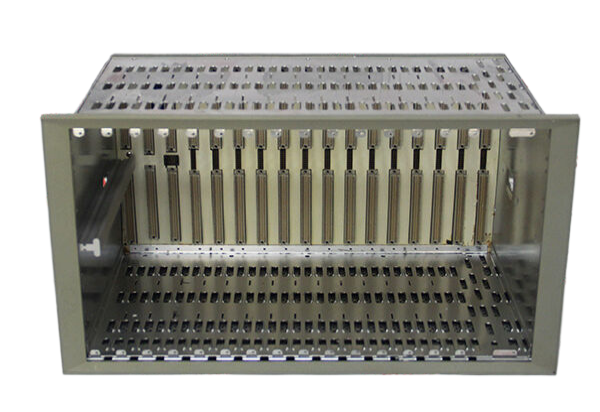

BENTLY Nevada 128275-01, Future Expansion Faceplate

Introducing the BENTLY Nevada, a cutting-edge solution in the realm of industrial monitoring and control, designed to enhance the reliability and efficiency of your operations. This model epitomizes BENTLY's commitment to excellence, featuring a robust set of technical characteristics that make it an indispensable tool for professionals in various industries.

Key Technical Features:

The BENTLY Nevada is engineered with advanced technology that ensures precision monitoring of machinery and equipment. With its high-resolution sensors and real-time data acquisition capabilities, it provides comprehensive insights into vibration, temperature, and other critical parameters. The device is equipped with a powerful processing unit that allows for seamless integration with existing BENTLY automation products, enhancing system interoperability. The user-friendly interface simplifies the monitoring process, while customizable alerts and analytics empower users to make informed decisions quickly. Furthermore, the BENTLY Nevada supports a wide range of communication protocols, ensuring compatibility with both legacy and modern systems.

Usage Scenarios:

The versatility of the BENTLY Nevada makes it ideal for a variety of applications across different sectors. In the oil and gas industry, it plays a pivotal role in monitoring rotating equipment, ensuring optimal performance and reducing downtime. In power generation, the BENTLY Nevada is critical for the condition monitoring of turbines and generators, allowing for proactive maintenance and operational efficiency. Additionally, it is widely used in manufacturing environments, where it helps track machinery health and prevent costly failures. Whether in a manufacturing plant, a power station, or an oil rig, the BENTLY Nevada stands as a reliable guardian of your operational integrity.

Comparison with Other Models:

When compared to other models in the BENTLY lineup, such as the BENTLY 3500/20 and BENTLY 3500/40M, the BENTLY Nevada shines with its enhanced data processing capabilities and user-friendly interface. While the BENTLY 3500 series offers dependable performance for vibration monitoring, the BENTLY Nevada expands on this foundation by integrating advanced analytics and more extensive communication options. In contrast to the BENTLY 3300/20 and BENTLY 3500/53, which focus primarily on specific monitoring needs, the BENTLY Nevada provides a holistic approach, making it suitable for complex systems requiring comprehensive oversight.

Related Models:

For those seeking to complement the BENTLY Nevada, several related models within the BENTLY family can enhance your monitoring capabilities. The BENTLY 3500/20 125744-02 and BENTLY 3500/45 176449-04 are excellent choices for vibration monitoring, while the BENTLY 3300/20-12-01-03-00-00 and BENTLY 3500/92 provide additional insights into machine health. The BENTLY 3500/50 and BENTLY 3500/53 offer robust data collection and analysis features, making them suitable companions for the BENTLY Nevada. Additionally, models like the BENTLY 3500

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY Nevada is engineered with advanced technology that ensures precision monitoring of machinery and equipment. With its high-resolution sensors and real-time data acquisition capabilities, it provides comprehensive insights into vibration, temperature, and other critical parameters. The device is equipped with a powerful processing unit that allows for seamless integration with existing BENTLY automation products, enhancing system interoperability. The user-friendly interface simplifies the monitoring process, while customizable alerts and analytics empower users to make informed decisions quickly. Furthermore, the BENTLY Nevada supports a wide range of communication protocols, ensuring compatibility with both legacy and modern systems.

Usage Scenarios:

The versatility of the BENTLY Nevada makes it ideal for a variety of applications across different sectors. In the oil and gas industry, it plays a pivotal role in monitoring rotating equipment, ensuring optimal performance and reducing downtime. In power generation, the BENTLY Nevada is critical for the condition monitoring of turbines and generators, allowing for proactive maintenance and operational efficiency. Additionally, it is widely used in manufacturing environments, where it helps track machinery health and prevent costly failures. Whether in a manufacturing plant, a power station, or an oil rig, the BENTLY Nevada stands as a reliable guardian of your operational integrity.

Comparison with Other Models:

When compared to other models in the BENTLY lineup, such as the BENTLY 3500/20 and BENTLY 3500/40M, the BENTLY Nevada shines with its enhanced data processing capabilities and user-friendly interface. While the BENTLY 3500 series offers dependable performance for vibration monitoring, the BENTLY Nevada expands on this foundation by integrating advanced analytics and more extensive communication options. In contrast to the BENTLY 3300/20 and BENTLY 3500/53, which focus primarily on specific monitoring needs, the BENTLY Nevada provides a holistic approach, making it suitable for complex systems requiring comprehensive oversight.

Related Models:

For those seeking to complement the BENTLY Nevada, several related models within the BENTLY family can enhance your monitoring capabilities. The BENTLY 3500/20 125744-02 and BENTLY 3500/45 176449-04 are excellent choices for vibration monitoring, while the BENTLY 3300/20-12-01-03-00-00 and BENTLY 3500/92 provide additional insights into machine health. The BENTLY 3500/50 and BENTLY 3500/53 offer robust data collection and analysis features, making them suitable companions for the BENTLY Nevada. Additionally, models like the BENTLY 3500

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.