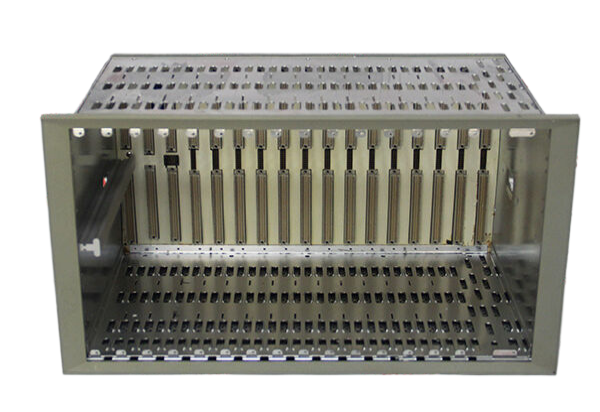

BENTLY 3500/25-01-00-00 3500 Series Vibration Monitoring System

Introducing the BENTLY 3500/25-01-00-00, a pinnacle of innovation in industrial automation. This advanced monitoring system is engineered to deliver unparalleled performance and reliability, making it an essential component in the BENTLY automation products lineup. The BENTLY 3500/25 model is specifically designed to provide comprehensive vibration monitoring, ensuring the optimal functioning of critical machinery in various industrial applications.

Key Technical Features:

The BENTLY 3500/25-01-00-00 boasts a robust set of technical features that enhances its functionality. It supports multi-channel capabilities, allowing for simultaneous monitoring of multiple assets, which significantly boosts operational efficiency. The model is equipped with advanced signal processing algorithms that accurately analyze vibration data, providing real-time insights into equipment health. With a high-speed sampling rate, the BENTLY 3500/25 ensures precise measurements, which are vital for predictive maintenance strategies.

The device also features a user-friendly interface, complete with intuitive software that simplifies configuration and data analysis. Its compatibility with the BENTLY 3500 Series enhances its versatility, allowing for seamless integration into existing systems. The rugged design of the BENTLY 3500/25 ensures durability in harsh industrial environments, making it an ideal choice for sectors such as oil and gas, power generation, and manufacturing.

Usage Scenarios:

The BENTLY 3500/25-01-00-00 is exceptionally versatile, finding applications across various industries. In the oil and gas sector, it plays a crucial role in monitoring rotating equipment such as pumps and compressors, helping to prevent costly downtime. In power generation, the device is essential for ensuring the reliability of turbines and generators by continuously tracking their performance. Furthermore, in manufacturing environments, it assists in monitoring production machinery, thereby enhancing overall productivity and reducing maintenance costs.

The model is particularly beneficial in scenarios where early detection of anomalies can save significant costs. By leveraging the BENTLY 3500/25’s advanced analytics, organizations can implement proactive maintenance schedules that extend equipment lifespan and improve operational efficiency.

Comparison with Other Models:

When compared to other models in the BENTLY product line, such as the BENTLY 3500/20 125744-02 and BENTLY 3500/40M, the 3500/25-01-00-00 stands out for its advanced vibration monitoring capabilities. While the BENTLY 3500/20 primarily focuses on general machinery health, the 3500/25 is specialized for vibration analysis, making it a more suitable option for applications requiring detailed monitoring. On the other hand, the BENTLY 3500/40M offers additional features for temperature monitoring, but the 3500/25 provides superior analysis for rotating equipment.

The BENTLY 3500/53 and BENTLY 3500/93 models also provide robust monitoring solutions; however, the 3500/25's dedicated focus on vibration data offers distinct

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY 3500/25-01-00-00 boasts a robust set of technical features that enhances its functionality. It supports multi-channel capabilities, allowing for simultaneous monitoring of multiple assets, which significantly boosts operational efficiency. The model is equipped with advanced signal processing algorithms that accurately analyze vibration data, providing real-time insights into equipment health. With a high-speed sampling rate, the BENTLY 3500/25 ensures precise measurements, which are vital for predictive maintenance strategies.

The device also features a user-friendly interface, complete with intuitive software that simplifies configuration and data analysis. Its compatibility with the BENTLY 3500 Series enhances its versatility, allowing for seamless integration into existing systems. The rugged design of the BENTLY 3500/25 ensures durability in harsh industrial environments, making it an ideal choice for sectors such as oil and gas, power generation, and manufacturing.

Usage Scenarios:

The BENTLY 3500/25-01-00-00 is exceptionally versatile, finding applications across various industries. In the oil and gas sector, it plays a crucial role in monitoring rotating equipment such as pumps and compressors, helping to prevent costly downtime. In power generation, the device is essential for ensuring the reliability of turbines and generators by continuously tracking their performance. Furthermore, in manufacturing environments, it assists in monitoring production machinery, thereby enhancing overall productivity and reducing maintenance costs.

The model is particularly beneficial in scenarios where early detection of anomalies can save significant costs. By leveraging the BENTLY 3500/25’s advanced analytics, organizations can implement proactive maintenance schedules that extend equipment lifespan and improve operational efficiency.

Comparison with Other Models:

When compared to other models in the BENTLY product line, such as the BENTLY 3500/20 125744-02 and BENTLY 3500/40M, the 3500/25-01-00-00 stands out for its advanced vibration monitoring capabilities. While the BENTLY 3500/20 primarily focuses on general machinery health, the 3500/25 is specialized for vibration analysis, making it a more suitable option for applications requiring detailed monitoring. On the other hand, the BENTLY 3500/40M offers additional features for temperature monitoring, but the 3500/25 provides superior analysis for rotating equipment.

The BENTLY 3500/53 and BENTLY 3500/93 models also provide robust monitoring solutions; however, the 3500/25's dedicated focus on vibration data offers distinct

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.