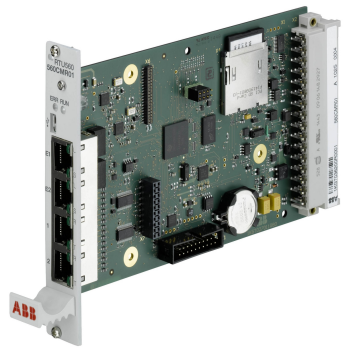

BENTLY 3500/22M 138607-01 Industrial Control Module

Introducing the BENTLY 3500/22M 138607-01, a cutting-edge component of the renowned BENTLY automation products line, designed to elevate your monitoring and protection capabilities. The BENTLY 3500 series is synonymous with reliability and precision in the field of industrial automation, and the 3500/22M model exemplifies that legacy with its advanced features and robust performance.

Key Technical Features

The BENTLY 3500/22M 138607-01 boasts a suite of technical features that make it an indispensable tool for any industrial application. This model is equipped with state-of-the-art vibration monitoring capabilities, allowing for real-time assessment of machinery performance. It offers a wide measurement range and high-resolution data acquisition, ensuring that you can detect even the smallest deviations from optimal operating conditions.

Additionally, the 3500/22M integrates seamlessly with the BENTLY 3500 series architecture, providing compatibility with other models such as the BENTLY 3500/20 125744-02, BENTLY 3500/45 176449-04, and BENTLY 3500/50, among others. This interoperability enhances the overall monitoring system, allowing you to configure a comprehensive monitoring solution tailored to your specific needs. With a user-friendly interface and extensive diagnostic capabilities, the BENTLY 3500/22M ensures that maintenance teams can quickly identify and resolve issues, reducing downtime and maintenance costs.

Usage Scenarios

The versatility of the BENTLY 3500/22M 138607-01 makes it suitable for a wide array of usage scenarios across various industries. Whether you are in oil and gas, power generation, or manufacturing, this model excels in providing critical insights into equipment health. It is particularly effective in monitoring rotating machinery such as pumps, compressors, and turbines, where early detection of issues is crucial to maintaining operational efficiency.

In scenarios where environmental conditions may be harsh, the BENTLY 3500/22M's robust design ensures reliable performance. Its ability to withstand extreme temperatures and vibrations makes it a preferred choice for facilities located in challenging environments. Furthermore, the real-time data provided by the 3500/22M empowers operators to make informed decisions quickly, enhancing safety and productivity on the floor.

Comparison with Other Models

When placing the BENTLY 3500/22M 138607-01 side by side with other models in the BENTLY lineup, such as the BENTLY 3500/40M or BENTLY 3500/34, it’s clear that each model serves unique purposes. While the 3500/40M focuses on comprehensive machinery protection, the 3500/22M is specifically tailored for vibration monitoring, making it more specialized in that aspect.

Additionally, the BENTLY 3500/92 and BENTLY 3500/50 models offer enhanced features for more complex machinery, but for organizations primarily

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The BENTLY 3500/22M 138607-01 boasts a suite of technical features that make it an indispensable tool for any industrial application. This model is equipped with state-of-the-art vibration monitoring capabilities, allowing for real-time assessment of machinery performance. It offers a wide measurement range and high-resolution data acquisition, ensuring that you can detect even the smallest deviations from optimal operating conditions.

Additionally, the 3500/22M integrates seamlessly with the BENTLY 3500 series architecture, providing compatibility with other models such as the BENTLY 3500/20 125744-02, BENTLY 3500/45 176449-04, and BENTLY 3500/50, among others. This interoperability enhances the overall monitoring system, allowing you to configure a comprehensive monitoring solution tailored to your specific needs. With a user-friendly interface and extensive diagnostic capabilities, the BENTLY 3500/22M ensures that maintenance teams can quickly identify and resolve issues, reducing downtime and maintenance costs.

Usage Scenarios

The versatility of the BENTLY 3500/22M 138607-01 makes it suitable for a wide array of usage scenarios across various industries. Whether you are in oil and gas, power generation, or manufacturing, this model excels in providing critical insights into equipment health. It is particularly effective in monitoring rotating machinery such as pumps, compressors, and turbines, where early detection of issues is crucial to maintaining operational efficiency.

In scenarios where environmental conditions may be harsh, the BENTLY 3500/22M's robust design ensures reliable performance. Its ability to withstand extreme temperatures and vibrations makes it a preferred choice for facilities located in challenging environments. Furthermore, the real-time data provided by the 3500/22M empowers operators to make informed decisions quickly, enhancing safety and productivity on the floor.

Comparison with Other Models

When placing the BENTLY 3500/22M 138607-01 side by side with other models in the BENTLY lineup, such as the BENTLY 3500/40M or BENTLY 3500/34, it’s clear that each model serves unique purposes. While the 3500/40M focuses on comprehensive machinery protection, the 3500/22M is specifically tailored for vibration monitoring, making it more specialized in that aspect.

Additionally, the BENTLY 3500/92 and BENTLY 3500/50 models offer enhanced features for more complex machinery, but for organizations primarily

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.