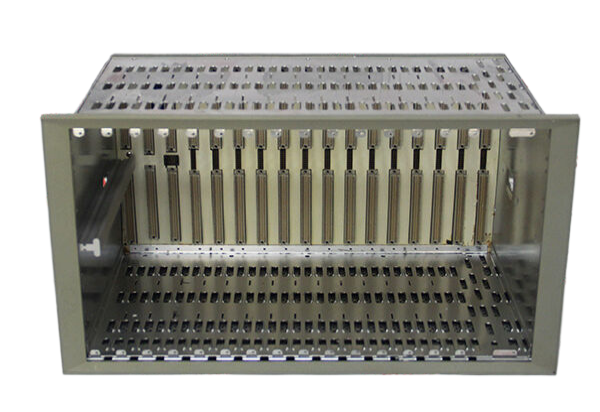

BENTLY 3500/15 129489-01 Control Module

Introducing the BENTLY 3500/15, a pinnacle of reliability and performance in the realm of condition monitoring and predictive maintenance. This advanced system is designed to offer unparalleled insights into your machinery's health, ensuring optimal operation and extending the lifespan of your assets.

Key Technical Features:

The BENTLY 3500/15 comes equipped with an array of cutting-edge features that set it apart from its competitors. It utilizes a modular architecture, allowing for easy customization and scalability to meet your specific application needs. With its exceptional analog input capability, it can handle a wide range of signal types, including velocity, displacement, and acceleration, making it compatible with various sensors and transducers. The device also supports advanced diagnostic capabilities, providing real-time data analysis and trend monitoring, which is crucial for predictive maintenance strategies. Additionally, the BENTLY 3500/15 is designed for seamless integration with other BENTLY automation products, enhancing your operational efficiency.

Usage Scenarios:

The versatility of the BENTLY 3500/15 makes it ideal for various industrial applications. It is particularly effective in monitoring rotating machinery such as pumps, turbines, and compressors, where vibration analysis is critical for preventing unexpected failures. In the oil and gas industry, the BENTLY 3500/15 plays a vital role in maintaining equipment reliability amidst demanding operational environments. It is equally valuable in power generation facilities, ensuring that critical assets operate smoothly and efficiently. By employing the BENTLY 3500/15, industrial operators can significantly reduce downtime, lower maintenance costs, and improve overall productivity.

Comparison with Other Models:

When comparing the BENTLY 3500/15 to other models in the BENTLY range, such as the BENTLY 3500/20 and BENTLY 3500/40M, the BENTLY 3500/15 stands out for its specialized focus on vibration monitoring and condition assessment. While the BENTLY 3500/20 offers enhanced capabilities for machinery protection, the BENTLY 3500/15 is tailored for in-depth analysis and diagnostics. The BENTLY 3500/40M, on the other hand, is designed for comprehensive monitoring of various industrial applications but may lack the specific features that allow the BENTLY 3500/15 to excel in vibration analysis. Each model serves unique functions, but the BENTLY 3500/15’s focus on precise condition monitoring makes it an indispensable tool for maintenance professionals.

Related Models:

For those interested in exploring other options within the BENTLY product line, consider the following related models: BENTLY 3500/20 125744-02, BENTLY 3500/40M 176449-01, BENTLY 3500/25, BENTLY 3500/34, BENTLY 3500/42M, BENTLY 3500/53 133388-01, BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY 3500/15 comes equipped with an array of cutting-edge features that set it apart from its competitors. It utilizes a modular architecture, allowing for easy customization and scalability to meet your specific application needs. With its exceptional analog input capability, it can handle a wide range of signal types, including velocity, displacement, and acceleration, making it compatible with various sensors and transducers. The device also supports advanced diagnostic capabilities, providing real-time data analysis and trend monitoring, which is crucial for predictive maintenance strategies. Additionally, the BENTLY 3500/15 is designed for seamless integration with other BENTLY automation products, enhancing your operational efficiency.

Usage Scenarios:

The versatility of the BENTLY 3500/15 makes it ideal for various industrial applications. It is particularly effective in monitoring rotating machinery such as pumps, turbines, and compressors, where vibration analysis is critical for preventing unexpected failures. In the oil and gas industry, the BENTLY 3500/15 plays a vital role in maintaining equipment reliability amidst demanding operational environments. It is equally valuable in power generation facilities, ensuring that critical assets operate smoothly and efficiently. By employing the BENTLY 3500/15, industrial operators can significantly reduce downtime, lower maintenance costs, and improve overall productivity.

Comparison with Other Models:

When comparing the BENTLY 3500/15 to other models in the BENTLY range, such as the BENTLY 3500/20 and BENTLY 3500/40M, the BENTLY 3500/15 stands out for its specialized focus on vibration monitoring and condition assessment. While the BENTLY 3500/20 offers enhanced capabilities for machinery protection, the BENTLY 3500/15 is tailored for in-depth analysis and diagnostics. The BENTLY 3500/40M, on the other hand, is designed for comprehensive monitoring of various industrial applications but may lack the specific features that allow the BENTLY 3500/15 to excel in vibration analysis. Each model serves unique functions, but the BENTLY 3500/15’s focus on precise condition monitoring makes it an indispensable tool for maintenance professionals.

Related Models:

For those interested in exploring other options within the BENTLY product line, consider the following related models: BENTLY 3500/20 125744-02, BENTLY 3500/40M 176449-01, BENTLY 3500/25, BENTLY 3500/34, BENTLY 3500/42M, BENTLY 3500/53 133388-01, BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.