BENTLY 149992-01 Module for Industrial Control Systems

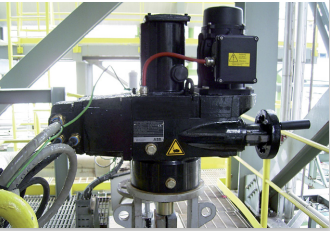

Introducing the BENTLY 149992-01, a premier solution in the realm of industrial automation and monitoring systems. Designed for accuracy and reliability, this model is an essential component for industries requiring high-performance condition monitoring and control. As part of the renowned BENTLY automation products line, the 149992-01 stands out for its exceptional technical features and versatile applications.

Key Technical Features:

The BENTLY 149992-01 is engineered with advanced technology that delivers precise measurements and real-time data analysis. This model boasts high-resolution sensors that provide unparalleled accuracy in monitoring critical parameters such as vibration, temperature, and pressure. With its robust design, the 149992-01 is built to withstand harsh industrial environments, ensuring longevity and durability. Additionally, it integrates seamlessly with existing BENTLY systems, offering compatibility with various models like the BENTLY 3500/20 (125744-02) and the BENTLY 3500/42M.

Equipped with advanced communication protocols, the BENTLY 149992-01 ensures seamless data transmission and integration with other industrial control systems. Its user-friendly interface allows for easy configuration and monitoring, enabling operators to quickly access vital information. The model also features built-in diagnostics, which proactively identify potential issues before they escalate, thus enhancing operational efficiency and reducing downtime.

Usage Scenarios:

The BENTLY 149992-01 is ideal for a wide array of applications across various industries, including oil and gas, power generation, and manufacturing. In the oil and gas sector, it is utilized for monitoring pumps, compressors, and turbines, ensuring optimal performance and safety. For power generation, the 149992-01 plays a critical role in monitoring generator sets and rotating equipment, allowing for predictive maintenance and minimizing operational risks.

In manufacturing, the versatility of the BENTLY 149992-01 makes it suitable for monitoring machinery such as conveyors, CNC machines, and other critical equipment. Its ability to provide real-time insights allows manufacturers to streamline processes, enhance productivity, and improve overall equipment effectiveness.

Comparison with Other Models:

When comparing the BENTLY 149992-01 with other models in the BENTLY automation products range, such as the BENTLY 3500/45 (176449-04) and the BENTLY 3500/50, it becomes evident that the 149992-01 offers unique advantages. While the 3500 series is known for its comprehensive monitoring capabilities, the 149992-01 excels in scenarios requiring high-precision measurements in harsh environments, making it a preferred choice for critical applications.

Furthermore, the BENTLY 149992-01 is designed to integrate effortlessly with models like the BENTLY Nevada and BENTLY 3300/16-11-01-03-00-00-01, providing a cohesive monitoring solution. Its advanced features position it favorably against models such as the BENTLY 3500/34 and BENT

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY 149992-01 is engineered with advanced technology that delivers precise measurements and real-time data analysis. This model boasts high-resolution sensors that provide unparalleled accuracy in monitoring critical parameters such as vibration, temperature, and pressure. With its robust design, the 149992-01 is built to withstand harsh industrial environments, ensuring longevity and durability. Additionally, it integrates seamlessly with existing BENTLY systems, offering compatibility with various models like the BENTLY 3500/20 (125744-02) and the BENTLY 3500/42M.

Equipped with advanced communication protocols, the BENTLY 149992-01 ensures seamless data transmission and integration with other industrial control systems. Its user-friendly interface allows for easy configuration and monitoring, enabling operators to quickly access vital information. The model also features built-in diagnostics, which proactively identify potential issues before they escalate, thus enhancing operational efficiency and reducing downtime.

Usage Scenarios:

The BENTLY 149992-01 is ideal for a wide array of applications across various industries, including oil and gas, power generation, and manufacturing. In the oil and gas sector, it is utilized for monitoring pumps, compressors, and turbines, ensuring optimal performance and safety. For power generation, the 149992-01 plays a critical role in monitoring generator sets and rotating equipment, allowing for predictive maintenance and minimizing operational risks.

In manufacturing, the versatility of the BENTLY 149992-01 makes it suitable for monitoring machinery such as conveyors, CNC machines, and other critical equipment. Its ability to provide real-time insights allows manufacturers to streamline processes, enhance productivity, and improve overall equipment effectiveness.

Comparison with Other Models:

When comparing the BENTLY 149992-01 with other models in the BENTLY automation products range, such as the BENTLY 3500/45 (176449-04) and the BENTLY 3500/50, it becomes evident that the 149992-01 offers unique advantages. While the 3500 series is known for its comprehensive monitoring capabilities, the 149992-01 excels in scenarios requiring high-precision measurements in harsh environments, making it a preferred choice for critical applications.

Furthermore, the BENTLY 149992-01 is designed to integrate effortlessly with models like the BENTLY Nevada and BENTLY 3300/16-11-01-03-00-00-01, providing a cohesive monitoring solution. Its advanced features position it favorably against models such as the BENTLY 3500/34 and BENT

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.