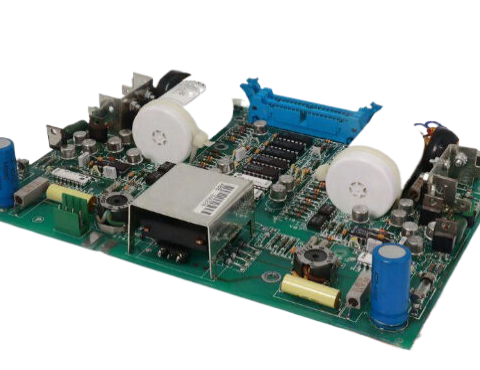

ABB IRB 7600 3HAC062341-005 Industrial Motor with Pinion, Precision Engineered for Efficiency and Durability

Introducing the ABB IRB 7600 3HAC062341-005, a robust and versatile industrial robot designed to meet the demands of various automation applications. This model stands out in the ABB lineup for its exceptional load capacity, precision, and reliability, making it an ideal choice for manufacturers looking to enhance productivity and efficiency.

Key Technical Features:

The ABB IRB 7600 is engineered with cutting-edge technology that enables it to deliver outstanding performance in a range of industrial settings. With a payload capacity of up to 300 kg, this robot is capable of handling heavy components with ease, making it perfect for industries such as automotive, metal fabrication, and heavy machinery. The robot boasts a reach of up to 3.2 meters, offering flexibility for complex tasks that require extended reach and precision.

Equipped with ABB’s advanced motion control technology, the IRB 7600 ensures high-speed operation while maintaining accuracy, which is crucial for tasks like welding, material handling, and assembly. The robot's compact design allows it to fit into tight spaces, optimizing your workflow. Additionally, the IRB 7600 is compatible with various end-of-arm tooling options, making it highly adaptable to diverse applications.

Usage Scenarios:

The ABB IRB 7600 3HAC062341-005 excels in various usage scenarios, including heavy-duty material handling, assembly line automation, and robotic welding. In automotive manufacturing, for instance, it can efficiently manage the assembly of large components, facilitating a streamlined production process. In the metalworking industry, its robust design and precision capabilities make it ideal for tasks such as cutting, welding, and machining.

Moreover, the robot’s ability to operate in harsh environments adds to its versatility. It can be deployed in foundries and machining centers where high temperatures and dust are prevalent. The ABB IRB 7600 is also suitable for collaborative environments, where it can work alongside human operators, enhancing safety and productivity.

Comparison with Other Models:

When compared to other models in the ABB portfolio, such as the IRB 2600 and the IRB 2400, the IRB 7600 stands out due to its superior payload capacity and reach. The IRB 2600, for example, offers a maximum payload of 20 kg, making it more suited for lighter applications, while the IRB 2400 is designed for medium-sized tasks. The IRB 7600, with its 300 kg capacity, is specifically tailored for heavy-duty applications, offering manufacturers the ability to handle larger components efficiently.

Additionally, while models like the ABB PP826 3BSE042244R1 and ABB PM511V16 3BSE011181R1 focus on process control and I/O modules, the IRB 7600 emphasizes robotic automation, providing greater flexibility in manufacturing environments.

Reference to Related Models:

For those exploring options within the ABB automation products range, consider these related models: ABB UNS1860B-P, ABB TU841 – 3BSE020848R1, ABB YPM106E YT204001-FN, ABB 3HAC16035-1, ABB ACS880-01-246A-3 3ABD00035954-D, ABB GINT5611C, ABB DC551-CS31, ABB 3HNP04014-1, and ABB 07DC91. Each of these models complements the ABB IRB 7600 in various industrial applications, offering solutions for different automation needs.

In conclusion, the ABB IRB 7600 3HAC062341-005 is an exceptional choice for any manufacturer seeking to automate heavy-duty tasks with precision and efficiency. Its advanced features, adaptability to diverse applications, and robust design make it a standout option among ABB automation products. Whether in automotive manufacturing, metal fabrication, or other industries, the IRB 7600 delivers unparalleled performance, setting a new standard in industrial automation.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The ABB IRB 7600 is engineered with cutting-edge technology that enables it to deliver outstanding performance in a range of industrial settings. With a payload capacity of up to 300 kg, this robot is capable of handling heavy components with ease, making it perfect for industries such as automotive, metal fabrication, and heavy machinery. The robot boasts a reach of up to 3.2 meters, offering flexibility for complex tasks that require extended reach and precision.

Equipped with ABB’s advanced motion control technology, the IRB 7600 ensures high-speed operation while maintaining accuracy, which is crucial for tasks like welding, material handling, and assembly. The robot's compact design allows it to fit into tight spaces, optimizing your workflow. Additionally, the IRB 7600 is compatible with various end-of-arm tooling options, making it highly adaptable to diverse applications.

Usage Scenarios:

The ABB IRB 7600 3HAC062341-005 excels in various usage scenarios, including heavy-duty material handling, assembly line automation, and robotic welding. In automotive manufacturing, for instance, it can efficiently manage the assembly of large components, facilitating a streamlined production process. In the metalworking industry, its robust design and precision capabilities make it ideal for tasks such as cutting, welding, and machining.

Moreover, the robot’s ability to operate in harsh environments adds to its versatility. It can be deployed in foundries and machining centers where high temperatures and dust are prevalent. The ABB IRB 7600 is also suitable for collaborative environments, where it can work alongside human operators, enhancing safety and productivity.

Comparison with Other Models:

When compared to other models in the ABB portfolio, such as the IRB 2600 and the IRB 2400, the IRB 7600 stands out due to its superior payload capacity and reach. The IRB 2600, for example, offers a maximum payload of 20 kg, making it more suited for lighter applications, while the IRB 2400 is designed for medium-sized tasks. The IRB 7600, with its 300 kg capacity, is specifically tailored for heavy-duty applications, offering manufacturers the ability to handle larger components efficiently.

Additionally, while models like the ABB PP826 3BSE042244R1 and ABB PM511V16 3BSE011181R1 focus on process control and I/O modules, the IRB 7600 emphasizes robotic automation, providing greater flexibility in manufacturing environments.

Reference to Related Models:

For those exploring options within the ABB automation products range, consider these related models: ABB UNS1860B-P, ABB TU841 – 3BSE020848R1, ABB YPM106E YT204001-FN, ABB 3HAC16035-1, ABB ACS880-01-246A-3 3ABD00035954-D, ABB GINT5611C, ABB DC551-CS31, ABB 3HNP04014-1, and ABB 07DC91. Each of these models complements the ABB IRB 7600 in various industrial applications, offering solutions for different automation needs.

In conclusion, the ABB IRB 7600 3HAC062341-005 is an exceptional choice for any manufacturer seeking to automate heavy-duty tasks with precision and efficiency. Its advanced features, adaptability to diverse applications, and robust design make it a standout option among ABB automation products. Whether in automotive manufacturing, metal fabrication, or other industries, the IRB 7600 delivers unparalleled performance, setting a new standard in industrial automation.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.