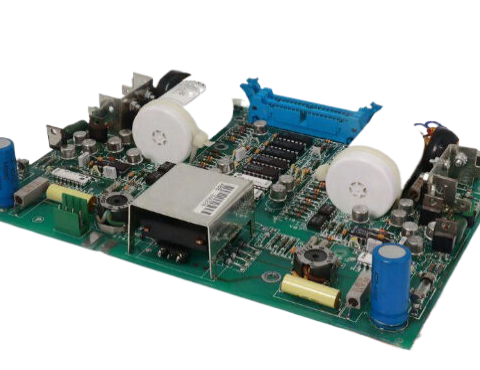

ABB IRB 4600 3HAC028837-006 Gearbox, Advanced Industrial Robot Component

Introducing the ABB IRB 4600 3HAC028837-006, a powerhouse in industrial automation designed to elevate your manufacturing processes with unparalleled precision and efficiency. This robotic arm is engineered for versatility and high performance, making it an ideal choice for various applications in diverse industries.

Key Technical Features:

The ABB IRB 4600 boasts a compact design that maximizes workspace efficiency while delivering a remarkable load capacity of up to 60 kg. With a reach of 1.8 meters, it excels in tasks that require both strength and agility. Its advanced motion control technology allows for high-speed operation without compromising accuracy, making it perfect for applications that demand quick cycle times. The robot is equipped with ABB's innovative IRC5 controller, which enables easy programming and integration into existing production lines. The IRB 4600 is also designed for flexibility, supporting a range of end-of-arm tooling and accessories to accommodate various tasks, such as material handling, welding, and assembly.

Usage Scenarios:

The ABB IRB 4600 is an exceptional choice for a multitude of industrial applications. In automotive manufacturing, it can handle heavy components with precision, ensuring that assembly lines operate at peak efficiency. In electronics, its dexterity allows for the delicate handling of small parts, reducing the risk of damage. Additionally, it is well-suited for packaging and palletizing tasks, seamlessly working alongside other ABB automation products to streamline operations. Whether you are looking to enhance productivity in a factory environment or automate complex processes, the IRB 4600 stands out as a reliable solution.

Comparison with Other Models:

When comparing the ABB IRB 4600 to other models in the ABB lineup, such as the IRB 2600 and IRB 2400/1403/CR3, its unique combination of reach and payload capacity sets it apart. While the IRB 2600 is known for its speed, the IRB 4600 offers a superior load capacity, making it more suitable for heavy-duty tasks. In contrast to the IRB 2400, which is designed for light to medium-duty applications, the IRB 4600 excels in environments where robust performance is critical. This makes it a preferred choice for manufacturers looking to tackle a wide range of challenges without compromising on reliability.

Related Models:

The ABB IRB 4600 is part of a stellar lineup of ABB automation products, including the ABB UNS1860B-P, V1, ABB PPE100A, ABB TU852 S800 I/O, ABB TU841, ABB IRB 2400, and ABB PM511V16. Each of these models brings unique capabilities to the table, catering to specific industrial needs. For instance, the ABB ACS880-01-246A-3 provides advanced motion control technologies that can complement the capabilities of the IRB 4600, enhancing overall system performance.

In addition, models like ABB DSQC352B and ABB NAIO-03F can be integrated with the IRB 4600 to create a comprehensive automation solution tailored to your production requirements. Whether you require high-speed handling or intricate assembly, the IRB 4600 can seamlessly operate alongside these related models, driving efficiency and productivity throughout your operations.

Conclusion:

The ABB IRB 4600 3HAC028837-006 is more than just a robotic arm; it is a vital component in the evolution of automated manufacturing. With its exceptional technical features, versatility in usage scenarios, and its ability to outperform other models, it is an investment that will propel your business forward. Explore the possibilities of ABB automation products and discover how the IRB 4600 can transform your operational capabilities today.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The ABB IRB 4600 boasts a compact design that maximizes workspace efficiency while delivering a remarkable load capacity of up to 60 kg. With a reach of 1.8 meters, it excels in tasks that require both strength and agility. Its advanced motion control technology allows for high-speed operation without compromising accuracy, making it perfect for applications that demand quick cycle times. The robot is equipped with ABB's innovative IRC5 controller, which enables easy programming and integration into existing production lines. The IRB 4600 is also designed for flexibility, supporting a range of end-of-arm tooling and accessories to accommodate various tasks, such as material handling, welding, and assembly.

Usage Scenarios:

The ABB IRB 4600 is an exceptional choice for a multitude of industrial applications. In automotive manufacturing, it can handle heavy components with precision, ensuring that assembly lines operate at peak efficiency. In electronics, its dexterity allows for the delicate handling of small parts, reducing the risk of damage. Additionally, it is well-suited for packaging and palletizing tasks, seamlessly working alongside other ABB automation products to streamline operations. Whether you are looking to enhance productivity in a factory environment or automate complex processes, the IRB 4600 stands out as a reliable solution.

Comparison with Other Models:

When comparing the ABB IRB 4600 to other models in the ABB lineup, such as the IRB 2600 and IRB 2400/1403/CR3, its unique combination of reach and payload capacity sets it apart. While the IRB 2600 is known for its speed, the IRB 4600 offers a superior load capacity, making it more suitable for heavy-duty tasks. In contrast to the IRB 2400, which is designed for light to medium-duty applications, the IRB 4600 excels in environments where robust performance is critical. This makes it a preferred choice for manufacturers looking to tackle a wide range of challenges without compromising on reliability.

Related Models:

The ABB IRB 4600 is part of a stellar lineup of ABB automation products, including the ABB UNS1860B-P, V1, ABB PPE100A, ABB TU852 S800 I/O, ABB TU841, ABB IRB 2400, and ABB PM511V16. Each of these models brings unique capabilities to the table, catering to specific industrial needs. For instance, the ABB ACS880-01-246A-3 provides advanced motion control technologies that can complement the capabilities of the IRB 4600, enhancing overall system performance.

In addition, models like ABB DSQC352B and ABB NAIO-03F can be integrated with the IRB 4600 to create a comprehensive automation solution tailored to your production requirements. Whether you require high-speed handling or intricate assembly, the IRB 4600 can seamlessly operate alongside these related models, driving efficiency and productivity throughout your operations.

Conclusion:

The ABB IRB 4600 3HAC028837-006 is more than just a robotic arm; it is a vital component in the evolution of automated manufacturing. With its exceptional technical features, versatility in usage scenarios, and its ability to outperform other models, it is an investment that will propel your business forward. Explore the possibilities of ABB automation products and discover how the IRB 4600 can transform your operational capabilities today.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.