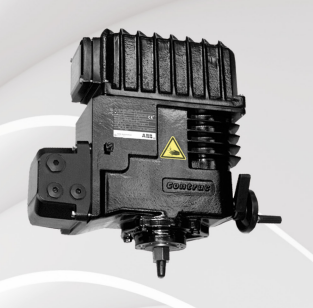

ABB IRB 1660 ID 3HAC059444-002 Advanced Industrial Robot Arm, Precision Manufacturing Solutions

Introducing the ABB IRB 1660 ID 3HAC059444-002, the latest addition to ABB's esteemed lineup of industrial robots designed to elevate automation capabilities across various sectors. This advanced robotic solution is engineered for precision, versatility, and efficiency, making it a perfect fit for a multitude of applications in manufacturing, assembly, and material handling.

Key Technical Features

The ABB IRB 1660 ID boasts a compact and lightweight design while delivering remarkable performance. With a payload capacity of up to 7 kg and a reach of 1.55 meters, this robot can handle a wide range of tasks with ease. It is equipped with a unique internal cable routing system that minimizes wear and tear on cables, ensuring longevity and reducing maintenance costs. The IRB 1660 ID features a high-speed and high-precision motion control system, allowing for rapid and accurate operations. Its advanced software capabilities provide seamless integration into existing systems and enable easy customization for specific applications.

One of the standout attributes of the ABB IRB 1660 ID is its flexibility. It can be outfitted with various end-effectors, enabling it to perform tasks such as pick-and-place, welding, packaging, and assembly. The robot's IP67-rated protection ensures durability in harsh environments, making it suitable for both cleanroom applications and challenging industrial settings.

Usage Scenarios

The ABB IRB 1660 ID is ideal for a wide array of industries, including automotive, electronics, consumer goods, and food and beverage. In automotive manufacturing, for instance, it can be employed for precision assembly of components or the handling of delicate parts without damage. In electronics, it excels in tasks like PCB assembly, where accuracy is paramount. The robot's quick adaptability allows it to switch between tasks effortlessly, making it an invaluable asset in dynamic production lines.

In the food and beverage sector, the IRB 1660 ID can be used for packaging and palletizing, ensuring consistent quality and efficiency in processes that demand hygiene and speed. Its lightweight design makes it suitable for installation in confined spaces, optimizing floor space and enhancing productivity.

Comparison with Other Models

When compared to other models in the ABB robotic lineup, such as the ABB IRB 2600 or the ABB IRB 2400, the IRB 1660 ID stands out for its unique combination of payload capacity, reach, and advanced internal cable management system. While the IRB 2600 is designed for higher payloads, the IRB 1660 ID provides a more compact solution without sacrificing performance. The IRB 2400, known for its versatility, is larger and may not fit well in tighter spaces, making the IRB 1660 ID a more suitable choice for applications where space is constrained.

Related Models

For those exploring ABB automation products, consider these related models that complement the capabilities of the ABB IRB 1660 ID: ABB IRB 2400/1403/CR3, ABB IRB 2600, ABB IRB 140 Series, ABB IRB 6700, ABB IRB 760, ABB IRB 6700, ABB 07DC91, ABB 3HAC16035-1, ABB PM511V16 3BSE011181R1, and ABB ACS880-01-246A-3 3ABD00035954-D. Each of these models brings unique features that cater to specific industrial needs, allowing businesses to find the perfect robotic solution for their operations.

In conclusion, the ABB IRB 1660 ID 3HAC059444-002 is a powerful and versatile industrial robot that enhances automation capabilities across various sectors. With its advanced technical features, adaptability to different tasks, and robust performance, it is an ideal choice for businesses looking to optimize their production processes. Embrace the future of automation with the ABB IRB 1660 ID and experience unparalleled efficiency and precision in your operations.

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The ABB IRB 1660 ID boasts a compact and lightweight design while delivering remarkable performance. With a payload capacity of up to 7 kg and a reach of 1.55 meters, this robot can handle a wide range of tasks with ease. It is equipped with a unique internal cable routing system that minimizes wear and tear on cables, ensuring longevity and reducing maintenance costs. The IRB 1660 ID features a high-speed and high-precision motion control system, allowing for rapid and accurate operations. Its advanced software capabilities provide seamless integration into existing systems and enable easy customization for specific applications.

One of the standout attributes of the ABB IRB 1660 ID is its flexibility. It can be outfitted with various end-effectors, enabling it to perform tasks such as pick-and-place, welding, packaging, and assembly. The robot's IP67-rated protection ensures durability in harsh environments, making it suitable for both cleanroom applications and challenging industrial settings.

Usage Scenarios

The ABB IRB 1660 ID is ideal for a wide array of industries, including automotive, electronics, consumer goods, and food and beverage. In automotive manufacturing, for instance, it can be employed for precision assembly of components or the handling of delicate parts without damage. In electronics, it excels in tasks like PCB assembly, where accuracy is paramount. The robot's quick adaptability allows it to switch between tasks effortlessly, making it an invaluable asset in dynamic production lines.

In the food and beverage sector, the IRB 1660 ID can be used for packaging and palletizing, ensuring consistent quality and efficiency in processes that demand hygiene and speed. Its lightweight design makes it suitable for installation in confined spaces, optimizing floor space and enhancing productivity.

Comparison with Other Models

When compared to other models in the ABB robotic lineup, such as the ABB IRB 2600 or the ABB IRB 2400, the IRB 1660 ID stands out for its unique combination of payload capacity, reach, and advanced internal cable management system. While the IRB 2600 is designed for higher payloads, the IRB 1660 ID provides a more compact solution without sacrificing performance. The IRB 2400, known for its versatility, is larger and may not fit well in tighter spaces, making the IRB 1660 ID a more suitable choice for applications where space is constrained.

Related Models

For those exploring ABB automation products, consider these related models that complement the capabilities of the ABB IRB 1660 ID: ABB IRB 2400/1403/CR3, ABB IRB 2600, ABB IRB 140 Series, ABB IRB 6700, ABB IRB 760, ABB IRB 6700, ABB 07DC91, ABB 3HAC16035-1, ABB PM511V16 3BSE011181R1, and ABB ACS880-01-246A-3 3ABD00035954-D. Each of these models brings unique features that cater to specific industrial needs, allowing businesses to find the perfect robotic solution for their operations.

In conclusion, the ABB IRB 1660 ID 3HAC059444-002 is a powerful and versatile industrial robot that enhances automation capabilities across various sectors. With its advanced technical features, adaptability to different tasks, and robust performance, it is an ideal choice for businesses looking to optimize their production processes. Embrace the future of automation with the ABB IRB 1660 ID and experience unparalleled efficiency and precision in your operations.

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.