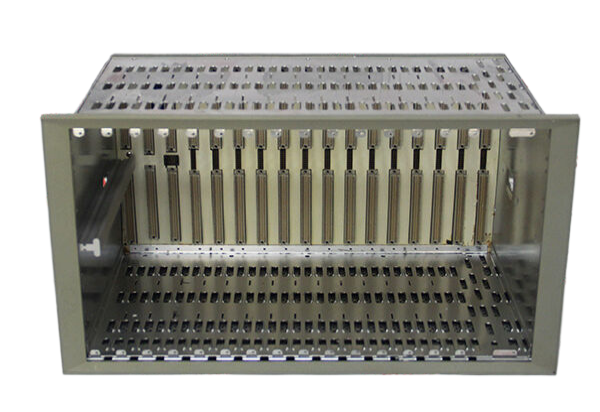

BENTLY Nevada 131151-01 Precision Measurement Solution for Industrial Control

Introducing the BENTLY Nevada 131151-01, a pivotal component in the realm of industrial automation and condition monitoring. Designed for precision and reliability, this model embodies the essence of BENTLY's commitment to excellence in automation products. Here’s an in-depth look at its key features, usage scenarios, and how it compares to other models within the BENTLY lineup.

Key Technical Features:

The BENTLY Nevada 131151-01 offers an impressive array of technical features tailored to meet the demands of modern industrial environments. It is equipped with advanced vibration monitoring capabilities, allowing for real-time assessment of machine health and performance. The device supports a wide range of measurement parameters, including displacement, velocity, and acceleration, ensuring comprehensive coverage for both rotating and non-rotating machinery.

One of its standout features is its robust communication protocol, enabling seamless integration with existing automation systems. With its high-resolution data acquisition and processing capabilities, the BENTLY Nevada 131151-01 can detect early signs of wear or misalignment, significantly reducing the risk of unexpected downtime. Additionally, the model boasts a user-friendly interface that simplifies setup and operation, making it accessible for both seasoned professionals and newcomers to the field.

Usage Scenarios:

The versatility of the BENTLY Nevada 131151-01 makes it an ideal choice for various industrial applications. Whether you’re in oil and gas, manufacturing, or power generation, this model excels in monitoring critical assets. For instance, in a manufacturing plant, it can monitor the health of motors, pumps, and compressors, ensuring they operate efficiently and reliably. In the oil and gas sector, it helps in tracking the condition of drilling equipment, preventing costly failures that can lead to significant production losses.

Moreover, the BENTLY Nevada 131151-01 is perfect for predictive maintenance programs, allowing organizations to transition from reactive to proactive maintenance strategies. By leveraging its advanced monitoring capabilities, businesses can schedule maintenance activities based on actual equipment condition rather than arbitrary timelines, optimizing resource allocation and enhancing overall operational efficiency.

Comparison with Other Models:

When comparing the BENTLY Nevada 131151-01 to other models in the BENTLY range, such as the BENTLY 3500/20 and BENTLY 3500/40M, it stands out for its specific focus on vibration monitoring. The BENTLY 3500/20, while also a robust monitoring solution, is more geared towards comprehensive machinery protection, encompassing a wider array of protection features beyond vibration analysis. Conversely, the BENTLY 3500/40M offers advanced monitoring as well but is tailored for different types of machinery and applications.

The BENTLY Nevada 131151-01 strikes a balance between specialized vibration analysis and versatility, making it an optimal choice for industries where vibration monitoring is crucial for operational success.

Related Models:

For customers exploring options within the BENTLY family of products, several related models may be of interest. These include the BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY Nevada 131151-01 offers an impressive array of technical features tailored to meet the demands of modern industrial environments. It is equipped with advanced vibration monitoring capabilities, allowing for real-time assessment of machine health and performance. The device supports a wide range of measurement parameters, including displacement, velocity, and acceleration, ensuring comprehensive coverage for both rotating and non-rotating machinery.

One of its standout features is its robust communication protocol, enabling seamless integration with existing automation systems. With its high-resolution data acquisition and processing capabilities, the BENTLY Nevada 131151-01 can detect early signs of wear or misalignment, significantly reducing the risk of unexpected downtime. Additionally, the model boasts a user-friendly interface that simplifies setup and operation, making it accessible for both seasoned professionals and newcomers to the field.

Usage Scenarios:

The versatility of the BENTLY Nevada 131151-01 makes it an ideal choice for various industrial applications. Whether you’re in oil and gas, manufacturing, or power generation, this model excels in monitoring critical assets. For instance, in a manufacturing plant, it can monitor the health of motors, pumps, and compressors, ensuring they operate efficiently and reliably. In the oil and gas sector, it helps in tracking the condition of drilling equipment, preventing costly failures that can lead to significant production losses.

Moreover, the BENTLY Nevada 131151-01 is perfect for predictive maintenance programs, allowing organizations to transition from reactive to proactive maintenance strategies. By leveraging its advanced monitoring capabilities, businesses can schedule maintenance activities based on actual equipment condition rather than arbitrary timelines, optimizing resource allocation and enhancing overall operational efficiency.

Comparison with Other Models:

When comparing the BENTLY Nevada 131151-01 to other models in the BENTLY range, such as the BENTLY 3500/20 and BENTLY 3500/40M, it stands out for its specific focus on vibration monitoring. The BENTLY 3500/20, while also a robust monitoring solution, is more geared towards comprehensive machinery protection, encompassing a wider array of protection features beyond vibration analysis. Conversely, the BENTLY 3500/40M offers advanced monitoring as well but is tailored for different types of machinery and applications.

The BENTLY Nevada 131151-01 strikes a balance between specialized vibration analysis and versatility, making it an optimal choice for industries where vibration monitoring is crucial for operational success.

Related Models:

For customers exploring options within the BENTLY family of products, several related models may be of interest. These include the BENTLY

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.