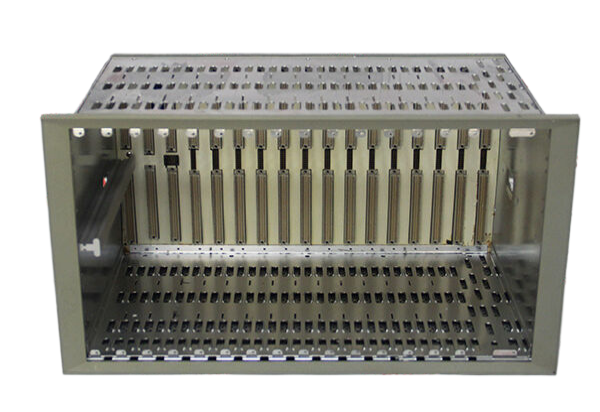

BENTLY 3500/34 125696-01 Vibration Monitoring Module

Introducing the BENTLY 3500/34, a cornerstone of precision monitoring within the realm of industrial automation. Designed to enhance the reliability and efficiency of your operational processes, the BENTLY 3500/34 stands out with its advanced technical features, seamless integration capabilities, and unparalleled performance.

Key Technical Features:

The BENTLY 3500/34 offers a robust array of features tailored for condition monitoring and machinery protection. It boasts a high-resolution measurement capability, ensuring accurate data collection for critical parameters such as vibration, temperature, and pressure. With its modular design, the BENTLY 3500/34 can be easily customized to suit specific application needs, providing flexibility in configurations. The unit supports multiple communication protocols, allowing for effortless integration with existing BENTLY automation products and third-party systems. Additionally, its intuitive user interface simplifies operation and enhances accessibility for technicians and engineers alike.

Usage Scenarios:

The BENTLY 3500/34 is ideal for a wide range of applications across various industries. It is particularly effective in environments where machinery reliability is paramount, such as power generation, oil and gas, mining, and manufacturing. For instance, in power plants, the BENTLY 3500/34 can monitor turbine health, providing early warnings of potential failures, thereby minimizing downtime and maintenance costs. In the oil and gas sector, the device can track the condition of compressors and pumps, ensuring they operate within safe limits. The versatility of the BENTLY 3500/34 makes it an essential tool for engineers and maintenance personnel dedicated to optimizing machinery performance and extending equipment lifespan.

Comparison with Other Models:

When compared to other models within the BENTLY range, such as the BENTLY 3500/20 and the BENTLY 3500/40M, the BENTLY 3500/34 offers enhanced functionality, particularly in its ability to handle more complex monitoring tasks. While the BENTLY 3500/20 is tailored for general-purpose vibration monitoring, the 3500/34 excels in multi-parameter measurement and analysis, making it a superior choice for applications that require comprehensive data. On the other hand, the BENTLY 3500/45 provides advanced diagnostics but may come at a higher cost. The BENTLY 3500/34 strikes a perfect balance between affordability and high-end performance, making it a preferred option for many industries.

Reference to Related Models:

For those exploring similar options within the BENTLY lineup, consider models such as the BENTLY 3500/50, known for its exceptional vibration analysis capabilities, or the BENTLY 3500/42M, which specializes in monitoring and diagnosing mechanical and thermal conditions. The BENTLY 3500/25 and BENTLY 3500/15 also offer reliable performance for specific monitoring needs. Additionally, the BENTLY 3300/16-11-01-03 and the BENTLY 330

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The BENTLY 3500/34 offers a robust array of features tailored for condition monitoring and machinery protection. It boasts a high-resolution measurement capability, ensuring accurate data collection for critical parameters such as vibration, temperature, and pressure. With its modular design, the BENTLY 3500/34 can be easily customized to suit specific application needs, providing flexibility in configurations. The unit supports multiple communication protocols, allowing for effortless integration with existing BENTLY automation products and third-party systems. Additionally, its intuitive user interface simplifies operation and enhances accessibility for technicians and engineers alike.

Usage Scenarios:

The BENTLY 3500/34 is ideal for a wide range of applications across various industries. It is particularly effective in environments where machinery reliability is paramount, such as power generation, oil and gas, mining, and manufacturing. For instance, in power plants, the BENTLY 3500/34 can monitor turbine health, providing early warnings of potential failures, thereby minimizing downtime and maintenance costs. In the oil and gas sector, the device can track the condition of compressors and pumps, ensuring they operate within safe limits. The versatility of the BENTLY 3500/34 makes it an essential tool for engineers and maintenance personnel dedicated to optimizing machinery performance and extending equipment lifespan.

Comparison with Other Models:

When compared to other models within the BENTLY range, such as the BENTLY 3500/20 and the BENTLY 3500/40M, the BENTLY 3500/34 offers enhanced functionality, particularly in its ability to handle more complex monitoring tasks. While the BENTLY 3500/20 is tailored for general-purpose vibration monitoring, the 3500/34 excels in multi-parameter measurement and analysis, making it a superior choice for applications that require comprehensive data. On the other hand, the BENTLY 3500/45 provides advanced diagnostics but may come at a higher cost. The BENTLY 3500/34 strikes a perfect balance between affordability and high-end performance, making it a preferred option for many industries.

Reference to Related Models:

For those exploring similar options within the BENTLY lineup, consider models such as the BENTLY 3500/50, known for its exceptional vibration analysis capabilities, or the BENTLY 3500/42M, which specializes in monitoring and diagnosing mechanical and thermal conditions. The BENTLY 3500/25 and BENTLY 3500/15 also offer reliable performance for specific monitoring needs. Additionally, the BENTLY 3300/16-11-01-03 and the BENTLY 330

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.