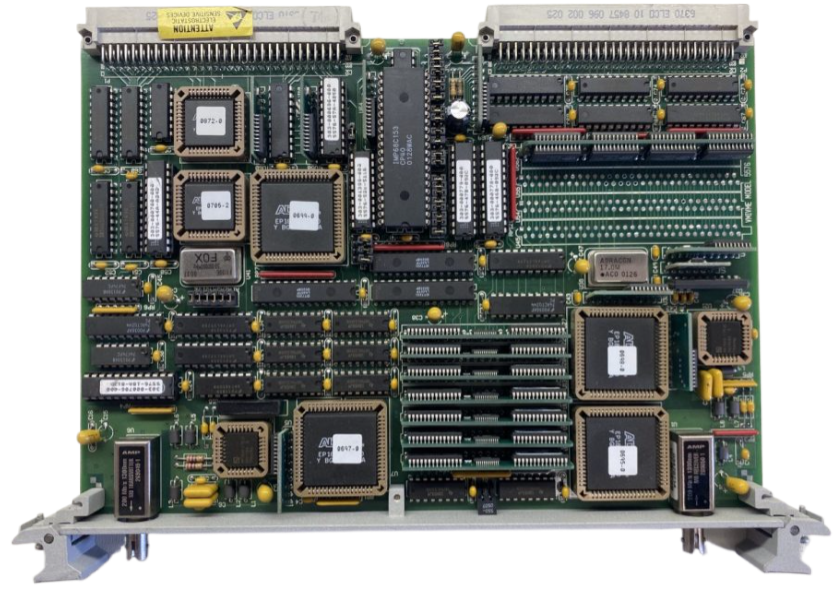

GE Fanuc IS200TPROH1B Protective Termination Card Advanced Automation for Industrial Turbines

Introducing the GE Fanuc, a pinnacle of engineering excellence in the world of automation technology. As a trusted name in industrial automation, GE Fanuc leads the charge with its innovative approach, providing robust solutions that streamline operations across various sectors. This product is designed for businesses seeking reliability, efficiency, and superior performance, making it an essential addition to your automation toolkit.

Key Technical Features:

The GE Fanuc is engineered with advanced capabilities that set it apart from competitors. It boasts a powerful processing unit that ensures high-speed data handling and real-time responsiveness. With a modular architecture, users can easily expand their systems to accommodate future growth. The model features an array of communication protocols, including Ethernet, Modbus, and Profibus, facilitating seamless integration with existing systems. Its high-resolution display and user-friendly interface enhance operational visibility, while built-in diagnostics provide instant feedback for troubleshooting and maintenance. Furthermore, the GE Fanuc is designed to operate in harsh industrial environments, ensuring longevity and reliability.

Usage Scenarios:

The versatility of GE Fanuc makes it suitable for various applications across multiple industries. In manufacturing, it can control complex machinery, manage production lines, and monitor equipment performance. In the oil and gas sector, the GE Fanuc is utilized for process automation, enabling real-time monitoring of pipelines and drilling operations. Additionally, in the logistics and warehousing sectors, it supports automated inventory management, optimizing the supply chain process. Its ability to handle multiple tasks simultaneously makes it a preferred choice for organizations looking to enhance productivity and reduce operational costs.

Comparison with Other Models:

While the GE Fanuc stands out on its own, it is essential to understand how it compares with other models in the GE family. For instance, the GE SR750 is known for its high-performance capabilities in data processing but may lack the modularity offered by the GE Fanuc. Similarly, the GE IS200DSPXH2DBD provides specialized control solutions but doesn't match the versatility of the GE Fanuc. On the other hand, models like the GE IC695CPE310-ABAH offer robust control features suited for specific applications, yet they may not cater to the broader operational needs that the GE Fanuc addresses. When considering scalability and comprehensive functionality, the GE Fanuc proves to be a superior option.

Related Models:

The GE Fanuc is part of an extensive lineup of GE automation products that complement its performance and expand its capabilities. Notable models include the GE IC697MDL740, which provides input/output modules for enhanced control, and the GE IS200DSFCG1AEB, known for its reliable digital signal processing. The GE IC660BBA020 serves as an excellent interface for communication between devices, while the GE DS200DDTBG2A focuses on digital input/output tasks. For those seeking advanced control features, the GE IS200DSPXH2DBD and GE IC200CPU005 are also worth considering. The GE IC3600A0AHIC is another robust option for specific industrial

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE Fanuc is engineered with advanced capabilities that set it apart from competitors. It boasts a powerful processing unit that ensures high-speed data handling and real-time responsiveness. With a modular architecture, users can easily expand their systems to accommodate future growth. The model features an array of communication protocols, including Ethernet, Modbus, and Profibus, facilitating seamless integration with existing systems. Its high-resolution display and user-friendly interface enhance operational visibility, while built-in diagnostics provide instant feedback for troubleshooting and maintenance. Furthermore, the GE Fanuc is designed to operate in harsh industrial environments, ensuring longevity and reliability.

Usage Scenarios:

The versatility of GE Fanuc makes it suitable for various applications across multiple industries. In manufacturing, it can control complex machinery, manage production lines, and monitor equipment performance. In the oil and gas sector, the GE Fanuc is utilized for process automation, enabling real-time monitoring of pipelines and drilling operations. Additionally, in the logistics and warehousing sectors, it supports automated inventory management, optimizing the supply chain process. Its ability to handle multiple tasks simultaneously makes it a preferred choice for organizations looking to enhance productivity and reduce operational costs.

Comparison with Other Models:

While the GE Fanuc stands out on its own, it is essential to understand how it compares with other models in the GE family. For instance, the GE SR750 is known for its high-performance capabilities in data processing but may lack the modularity offered by the GE Fanuc. Similarly, the GE IS200DSPXH2DBD provides specialized control solutions but doesn't match the versatility of the GE Fanuc. On the other hand, models like the GE IC695CPE310-ABAH offer robust control features suited for specific applications, yet they may not cater to the broader operational needs that the GE Fanuc addresses. When considering scalability and comprehensive functionality, the GE Fanuc proves to be a superior option.

Related Models:

The GE Fanuc is part of an extensive lineup of GE automation products that complement its performance and expand its capabilities. Notable models include the GE IC697MDL740, which provides input/output modules for enhanced control, and the GE IS200DSFCG1AEB, known for its reliable digital signal processing. The GE IC660BBA020 serves as an excellent interface for communication between devices, while the GE DS200DDTBG2A focuses on digital input/output tasks. For those seeking advanced control features, the GE IS200DSPXH2DBD and GE IC200CPU005 are also worth considering. The GE IC3600A0AHIC is another robust option for specific industrial

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.