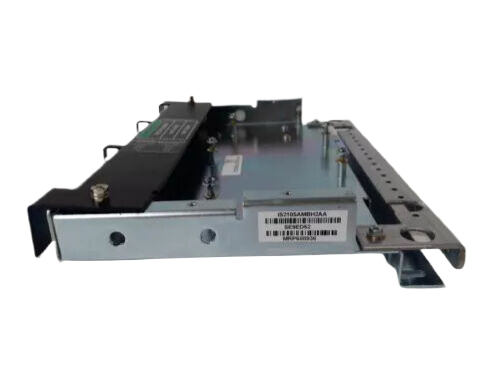

GE FANUC IC694ALG223 Advanced Logic Module for Industrial Control Systems

Introducing the GE FANUC – a cornerstone of reliability and innovation in the realm of industrial automation. Known for its robust performance and advanced technology, GE FANUC products are engineered to meet the rigorous demands of modern manufacturing environments.

Key Technical Features:

The GE FANUC model boasts a range of pivotal technical features designed to enhance operational efficiency and ensure seamless integration into existing systems. High-speed processing capabilities allow for rapid data handling, while its expandable architecture provides flexibility to adapt to evolving business needs. Equipped with advanced communication protocols, the GE FANUC facilitates efficient data exchange between devices, ensuring streamlined operations. The model also includes state-of-the-art diagnostic and troubleshooting functionalities, enabling quick identification of issues and minimizing downtime. With support for a variety of input and output configurations, the GE FANUC is truly versatile, able to accommodate a wide range of applications.

Usage Scenarios:

The GE FANUC is ideal for various industrial applications, including manufacturing, process control, and assembly automation. In a manufacturing setting, it can be deployed to monitor and control production lines, ensuring optimal performance and efficiency. In process control, the model's real-time data processing capabilities allow for precise monitoring and adjustment of system parameters, ensuring product quality and reducing waste. Furthermore, in assembly automation, the GE FANUC can synchronize multiple machines and robots, streamlining operations and enhancing productivity. Whether it's in automotive manufacturing, food and beverage processing, or material handling, the GE FANUC stands as a trusted solution for automation needs.

Comparison with Other Models:

When compared to other models within the GE automation products line, the GE FANUC distinguishes itself through its advanced processing power and flexible architecture. For instance, while the GE SR750 is known for its high reliability, the FANUC model takes it a step further with enhanced communication capabilities and scalability. Similarly, in contrast to the GE IS200DSFCG1AEB, which focuses on specialized applications, the GE FANUC provides a more generalized solution suitable for a wider array of industries. The GE IC697MDL740 is another noteworthy comparison, as it offers a robust set of features but lacks the same level of flexibility in terms of I/O configurations. The GE FANUC's ability to adapt to different operational requirements makes it a preferred choice for businesses looking for versatility alongside performance.

Related Models:

The GE FANUC is part of an extensive lineup of reliable automation solutions, including the GE IC660BBA020, GE DS200DDTBG2A, GE IS200DSPXH2DBD, and GE IC693APU301. Each of these models plays a crucial role in various sectors, providing specialized functions that complement the capabilities of the GE FANUC. Other notable mentions include the GE IS200EDFFH1ABA, which excels in process control applications, and the GE IC695CPE310-ABAH, known for its user-friendly interface and ease of integration. Additionally, the GE 469-P5-HI-A1-E-H offers advanced motor protection features,

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE FANUC model boasts a range of pivotal technical features designed to enhance operational efficiency and ensure seamless integration into existing systems. High-speed processing capabilities allow for rapid data handling, while its expandable architecture provides flexibility to adapt to evolving business needs. Equipped with advanced communication protocols, the GE FANUC facilitates efficient data exchange between devices, ensuring streamlined operations. The model also includes state-of-the-art diagnostic and troubleshooting functionalities, enabling quick identification of issues and minimizing downtime. With support for a variety of input and output configurations, the GE FANUC is truly versatile, able to accommodate a wide range of applications.

Usage Scenarios:

The GE FANUC is ideal for various industrial applications, including manufacturing, process control, and assembly automation. In a manufacturing setting, it can be deployed to monitor and control production lines, ensuring optimal performance and efficiency. In process control, the model's real-time data processing capabilities allow for precise monitoring and adjustment of system parameters, ensuring product quality and reducing waste. Furthermore, in assembly automation, the GE FANUC can synchronize multiple machines and robots, streamlining operations and enhancing productivity. Whether it's in automotive manufacturing, food and beverage processing, or material handling, the GE FANUC stands as a trusted solution for automation needs.

Comparison with Other Models:

When compared to other models within the GE automation products line, the GE FANUC distinguishes itself through its advanced processing power and flexible architecture. For instance, while the GE SR750 is known for its high reliability, the FANUC model takes it a step further with enhanced communication capabilities and scalability. Similarly, in contrast to the GE IS200DSFCG1AEB, which focuses on specialized applications, the GE FANUC provides a more generalized solution suitable for a wider array of industries. The GE IC697MDL740 is another noteworthy comparison, as it offers a robust set of features but lacks the same level of flexibility in terms of I/O configurations. The GE FANUC's ability to adapt to different operational requirements makes it a preferred choice for businesses looking for versatility alongside performance.

Related Models:

The GE FANUC is part of an extensive lineup of reliable automation solutions, including the GE IC660BBA020, GE DS200DDTBG2A, GE IS200DSPXH2DBD, and GE IC693APU301. Each of these models plays a crucial role in various sectors, providing specialized functions that complement the capabilities of the GE FANUC. Other notable mentions include the GE IS200EDFFH1ABA, which excels in process control applications, and the GE IC695CPE310-ABAH, known for its user-friendly interface and ease of integration. Additionally, the GE 469-P5-HI-A1-E-H offers advanced motor protection features,

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.