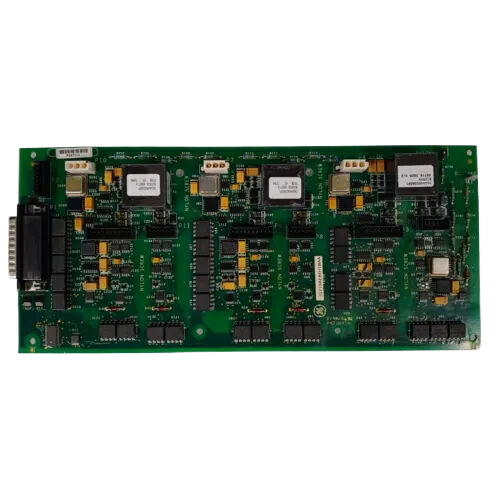

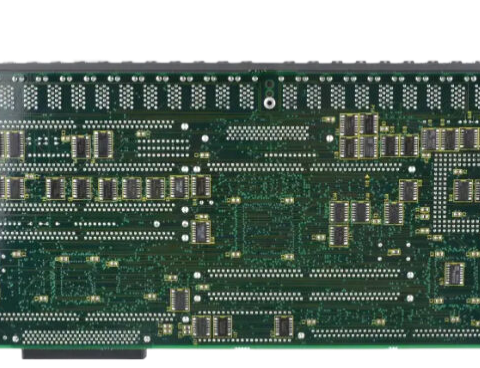

GE FANUC IC697CLG440 Current Expander Module Control

Introducing the GE FANUC: the pinnacle of automation technology tailored for diverse industrial applications. Renowned for its reliability and cutting-edge performance, the GE FANUC empowers businesses to enhance productivity and streamline operations. This product description delves into the key technical features, usage scenarios, and how it compares to other models, while referencing related products to provide a comprehensive overview.

Key Technical Features:

The GE FANUC boasts an impressive array of technical features designed to cater to the demanding requirements of modern industrial environments. It integrates seamlessly with GE automation products, providing robust control capabilities. Key features include:

1. **Modular Design**: The GE FANUC features a modular design that allows for easy scalability and customization, enabling users to tailor the system to their specific needs.

2. **High Processing Speed**: Equipped with advanced processing capabilities, the GE FANUC ensures rapid data handling and response times, making it ideal for high-speed applications.

3. **Versatile Communication Protocols**: Supporting a wide range of communication protocols, including Ethernet and serial communication, the GE FANUC connects effortlessly with various devices and systems, enhancing interoperability.

4. **Robust Diagnostics**: The built-in diagnostic tools facilitate efficient troubleshooting, significantly reducing downtime and maintenance costs.

5. **Enhanced Security Features**: With integrated security measures, the GE FANUC protects sensitive data and ensures that operations remain secure against cyber threats.

Usage Scenarios:

The GE FANUC is engineered for versatility, making it suitable for a myriad of industries and applications. Here are a few scenarios where this model excels:

1. **Manufacturing Automation**: Ideal for assembly line automation, the GE FANUC enhances precision and efficiency in manufacturing processes, ensuring high-quality output while minimizing waste.

2. **Energy Management**: In the energy sector, the GE FANUC plays a crucial role in monitoring and controlling power generation and distribution systems, optimizing energy usage, and improving sustainability.

3. **Process Control**: The model is widely used in chemical and food processing industries, where precise control over variables like temperature, pressure, and flow rates is critical for product quality and safety.

4. **Transportation Systems**: Implemented in intelligent transportation systems, the GE FANUC helps manage traffic signals, monitor vehicle conditions, and enhance public transportation efficiency.

Comparison with Other Models:

When compared to other models within the GE portfolio, such as the GE SR750 and GE IS200DSPXH2DBD, the GE FANUC stands out for its superior processing power and modular design. While the GE SR750 is known for its reliability in critical control applications, the GE FANUC offers enhanced versatility, making it more suitable for diverse industrial scenarios. Additionally, unlike the GE IS200DSPXH2DBD, which is optimized for specific applications, the GE FANUC provides a more comprehensive solution for multi-faceted automation needs.

Related Models:

To give you a broader view of the GE automation products ecosystem, consider these models that complement the GE FANUC:

1

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE FANUC boasts an impressive array of technical features designed to cater to the demanding requirements of modern industrial environments. It integrates seamlessly with GE automation products, providing robust control capabilities. Key features include:

1. **Modular Design**: The GE FANUC features a modular design that allows for easy scalability and customization, enabling users to tailor the system to their specific needs.

2. **High Processing Speed**: Equipped with advanced processing capabilities, the GE FANUC ensures rapid data handling and response times, making it ideal for high-speed applications.

3. **Versatile Communication Protocols**: Supporting a wide range of communication protocols, including Ethernet and serial communication, the GE FANUC connects effortlessly with various devices and systems, enhancing interoperability.

4. **Robust Diagnostics**: The built-in diagnostic tools facilitate efficient troubleshooting, significantly reducing downtime and maintenance costs.

5. **Enhanced Security Features**: With integrated security measures, the GE FANUC protects sensitive data and ensures that operations remain secure against cyber threats.

Usage Scenarios:

The GE FANUC is engineered for versatility, making it suitable for a myriad of industries and applications. Here are a few scenarios where this model excels:

1. **Manufacturing Automation**: Ideal for assembly line automation, the GE FANUC enhances precision and efficiency in manufacturing processes, ensuring high-quality output while minimizing waste.

2. **Energy Management**: In the energy sector, the GE FANUC plays a crucial role in monitoring and controlling power generation and distribution systems, optimizing energy usage, and improving sustainability.

3. **Process Control**: The model is widely used in chemical and food processing industries, where precise control over variables like temperature, pressure, and flow rates is critical for product quality and safety.

4. **Transportation Systems**: Implemented in intelligent transportation systems, the GE FANUC helps manage traffic signals, monitor vehicle conditions, and enhance public transportation efficiency.

Comparison with Other Models:

When compared to other models within the GE portfolio, such as the GE SR750 and GE IS200DSPXH2DBD, the GE FANUC stands out for its superior processing power and modular design. While the GE SR750 is known for its reliability in critical control applications, the GE FANUC offers enhanced versatility, making it more suitable for diverse industrial scenarios. Additionally, unlike the GE IS200DSPXH2DBD, which is optimized for specific applications, the GE FANUC provides a more comprehensive solution for multi-faceted automation needs.

Related Models:

To give you a broader view of the GE automation products ecosystem, consider these models that complement the GE FANUC:

1

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.