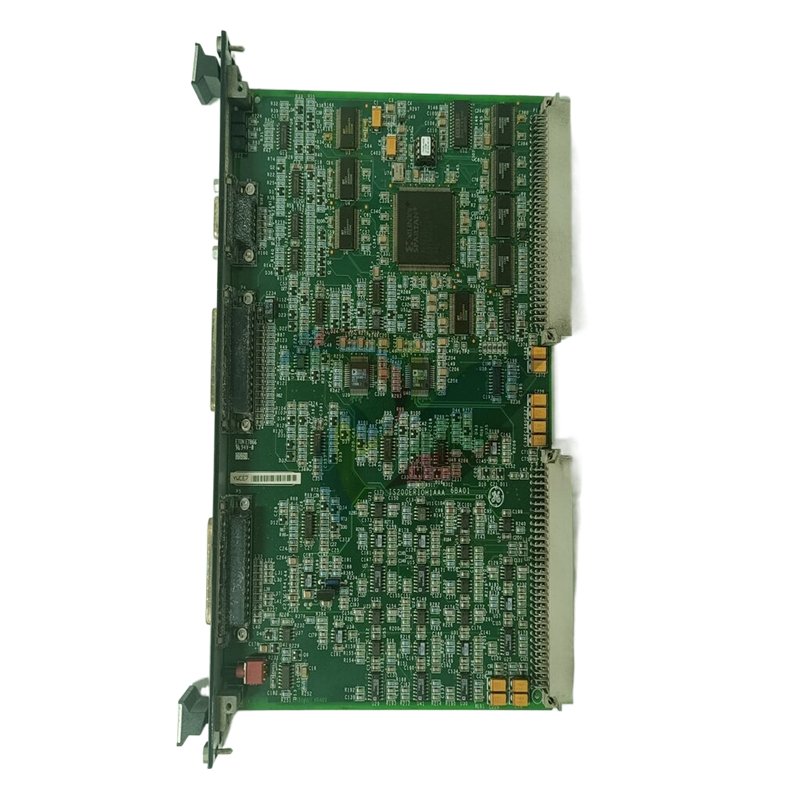

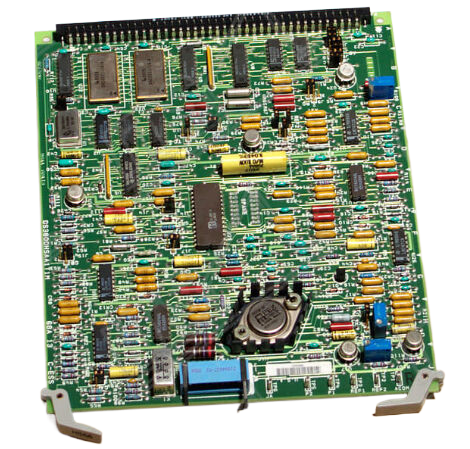

GE Fanuc IS215UCVGH1A Industrial Control Card

Introducing the GE Fanuc: the pinnacle of industrial automation technology designed to enhance productivity and efficiency across a variety of applications. As part of GE’s extensive range of automation products, the GE Fanuc offers a suite of advanced features that cater to the demanding needs of modern manufacturing and process control environments.

Key Technical Features:

The GE Fanuc is engineered with cutting-edge technology to ensure reliability and performance. It boasts a powerful processor capable of executing complex algorithms and real-time data processing. With high-speed communication capabilities, the GE Fanuc facilitates seamless integration into existing systems, allowing for enhanced data exchange between devices. The unit supports a diverse range of I/O modules, ensuring compatibility with various sensors and actuators, which makes it highly versatile for different applications.

Moreover, the GE Fanuc features robust diagnostic and troubleshooting tools, enabling quick identification of issues and reducing downtime. It also includes user-friendly programming interfaces that simplify the development and deployment of control applications. The unit supports multiple communication protocols, making it an ideal choice for diverse industrial environments. With an emphasis on durability, the GE Fanuc is built to withstand harsh operating conditions, ensuring long-lasting performance.

Usage Scenarios:

The GE Fanuc is suitable for a wide array of industries, including automotive, oil and gas, food and beverage, and pharmaceuticals. In automotive manufacturing, it can be used for assembly line automation, allowing for precise control of robotic arms and conveyor systems. In the oil and gas sector, the GE Fanuc can monitor and control drilling operations, ensuring safety and efficiency in remote locations. In food and beverage production, it helps maintain quality control and consistency in manufacturing processes.

Additionally, the GE Fanuc can be utilized in water treatment facilities for real-time monitoring and control of chemical dosing and filtration systems. Its adaptability makes it a crucial component in smart factory initiatives, where real-time data analytics and machine learning are leveraged to optimize production processes.

Comparison with Other Models:

When comparing the GE Fanuc to other models within the GE automation product line, such as the GE SR750 or the GE IC697MDL740, the GE Fanuc stands out due to its enhanced processing power and versatile communication capabilities. While models like the GE IS200DSPXH2DBD offer specific functionalities tailored for certain applications, the GE Fanuc provides a more comprehensive solution that can be adapted to various industrial settings.

The GE IC695CPE310-ABAH, for instance, is known for its high-speed connectivity; however, the GE Fanuc surpasses it with superior data processing capabilities, making it a preferred choice for organizations looking to future-proof their automation solutions. In contrast to the GE DS200DDTBG2A, which may be limited in scope, the GE Fanuc is designed to handle a broader range of tasks and integrate seamlessly with other GE automation products.

Related Models:

For those interested in exploring additional options within the GE automation product range, related models include the GE IC200CPU005, GE IS200TRPGH1B

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE Fanuc is engineered with cutting-edge technology to ensure reliability and performance. It boasts a powerful processor capable of executing complex algorithms and real-time data processing. With high-speed communication capabilities, the GE Fanuc facilitates seamless integration into existing systems, allowing for enhanced data exchange between devices. The unit supports a diverse range of I/O modules, ensuring compatibility with various sensors and actuators, which makes it highly versatile for different applications.

Moreover, the GE Fanuc features robust diagnostic and troubleshooting tools, enabling quick identification of issues and reducing downtime. It also includes user-friendly programming interfaces that simplify the development and deployment of control applications. The unit supports multiple communication protocols, making it an ideal choice for diverse industrial environments. With an emphasis on durability, the GE Fanuc is built to withstand harsh operating conditions, ensuring long-lasting performance.

Usage Scenarios:

The GE Fanuc is suitable for a wide array of industries, including automotive, oil and gas, food and beverage, and pharmaceuticals. In automotive manufacturing, it can be used for assembly line automation, allowing for precise control of robotic arms and conveyor systems. In the oil and gas sector, the GE Fanuc can monitor and control drilling operations, ensuring safety and efficiency in remote locations. In food and beverage production, it helps maintain quality control and consistency in manufacturing processes.

Additionally, the GE Fanuc can be utilized in water treatment facilities for real-time monitoring and control of chemical dosing and filtration systems. Its adaptability makes it a crucial component in smart factory initiatives, where real-time data analytics and machine learning are leveraged to optimize production processes.

Comparison with Other Models:

When comparing the GE Fanuc to other models within the GE automation product line, such as the GE SR750 or the GE IC697MDL740, the GE Fanuc stands out due to its enhanced processing power and versatile communication capabilities. While models like the GE IS200DSPXH2DBD offer specific functionalities tailored for certain applications, the GE Fanuc provides a more comprehensive solution that can be adapted to various industrial settings.

The GE IC695CPE310-ABAH, for instance, is known for its high-speed connectivity; however, the GE Fanuc surpasses it with superior data processing capabilities, making it a preferred choice for organizations looking to future-proof their automation solutions. In contrast to the GE DS200DDTBG2A, which may be limited in scope, the GE Fanuc is designed to handle a broader range of tasks and integrate seamlessly with other GE automation products.

Related Models:

For those interested in exploring additional options within the GE automation product range, related models include the GE IC200CPU005, GE IS200TRPGH1B

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.