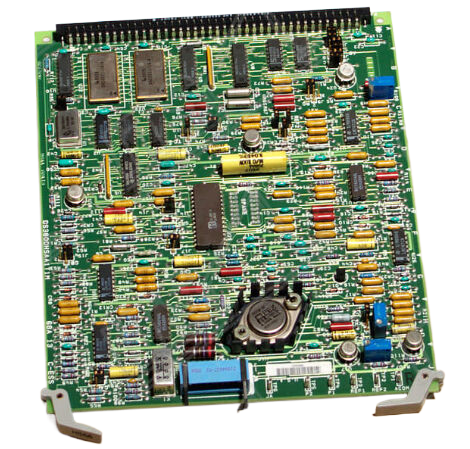

GE Fanuc IC200GB1001 High Performance VersaMax PLC Module

Introducing the GE Fanuc, a cornerstone of GE's automation products that seamlessly combines advanced technology with user-friendly functionality. Designed to meet the rigorous demands of industrial automation, the GE Fanuc model excels in performance, reliability, and adaptability across various applications.

Key Technical Features:

The GE Fanuc is built with a robust architecture that ensures high efficiency and longevity. Key features include:

1. **High Processing Power:** The GE Fanuc is equipped with a powerful processor that allows for rapid data processing and real-time control, making it ideal for complex automation tasks.

2. **Versatile Communication Protocols:** With support for multiple communication protocols, including Ethernet/IP, Modbus, and serial communication, the GE Fanuc integrates effortlessly with other GE automation products and third-party devices.

3. **Scalability:** This model supports a wide range of I/O configurations, making it easy to scale your automation solutions as your needs evolve. This flexibility is a significant advantage for diverse industries, from manufacturing to energy.

4. **Robust Input/Output Options:** The GE Fanuc features a rich set of input and output options, allowing it to handle a variety of sensors and actuators efficiently. This versatility is vital for applications that require precise and responsive control.

5. **Enhanced Security Features:** With built-in security protocols, the GE Fanuc safeguards your operations against unauthorized access, ensuring the integrity of your data and processes.

Usage Scenarios:

The GE Fanuc is designed for a multitude of applications, serving industries such as manufacturing, oil and gas, water treatment, and transportation. For example, in a manufacturing environment, the GE Fanuc can control assembly lines, monitor machine performance, and optimize production schedules. In the oil and gas sector, it can be utilized for process control, ensuring safety and efficiency in extraction and refining operations. Water treatment facilities benefit from the GE Fanuc's ability to manage complex systems that require precise control over chemical dosing and water quality monitoring.

Comparison with Other Models:

When compared to other models in the GE automation lineup, such as the GE SR750 and GE IC693APU301, the GE Fanuc stands out due to its enhanced processing capabilities and broader communication options. While the GE SR750 is tailored for specific high-performance applications, the GE Fanuc offers more versatility across various industrial processes. Additionally, in comparison to models like the GE IS200DSPXH2DBD, known for its specialized functionalities, the GE Fanuc provides a more comprehensive solution suited for diverse scenarios.

Related Models:

For those exploring GE automation products, consider the following related models:

1. GE SR750

2. GE IC697MDL740

3. GE IS200DSFCG1AEB

4. GE IC660BBA020

5. GE DS200DDTBG2A

6. GE IS200DSPXH2DBD

7. GE IC693ACC302

8. GE IS200TRPGH1BDE

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE Fanuc is built with a robust architecture that ensures high efficiency and longevity. Key features include:

1. **High Processing Power:** The GE Fanuc is equipped with a powerful processor that allows for rapid data processing and real-time control, making it ideal for complex automation tasks.

2. **Versatile Communication Protocols:** With support for multiple communication protocols, including Ethernet/IP, Modbus, and serial communication, the GE Fanuc integrates effortlessly with other GE automation products and third-party devices.

3. **Scalability:** This model supports a wide range of I/O configurations, making it easy to scale your automation solutions as your needs evolve. This flexibility is a significant advantage for diverse industries, from manufacturing to energy.

4. **Robust Input/Output Options:** The GE Fanuc features a rich set of input and output options, allowing it to handle a variety of sensors and actuators efficiently. This versatility is vital for applications that require precise and responsive control.

5. **Enhanced Security Features:** With built-in security protocols, the GE Fanuc safeguards your operations against unauthorized access, ensuring the integrity of your data and processes.

Usage Scenarios:

The GE Fanuc is designed for a multitude of applications, serving industries such as manufacturing, oil and gas, water treatment, and transportation. For example, in a manufacturing environment, the GE Fanuc can control assembly lines, monitor machine performance, and optimize production schedules. In the oil and gas sector, it can be utilized for process control, ensuring safety and efficiency in extraction and refining operations. Water treatment facilities benefit from the GE Fanuc's ability to manage complex systems that require precise control over chemical dosing and water quality monitoring.

Comparison with Other Models:

When compared to other models in the GE automation lineup, such as the GE SR750 and GE IC693APU301, the GE Fanuc stands out due to its enhanced processing capabilities and broader communication options. While the GE SR750 is tailored for specific high-performance applications, the GE Fanuc offers more versatility across various industrial processes. Additionally, in comparison to models like the GE IS200DSPXH2DBD, known for its specialized functionalities, the GE Fanuc provides a more comprehensive solution suited for diverse scenarios.

Related Models:

For those exploring GE automation products, consider the following related models:

1. GE SR750

2. GE IC697MDL740

3. GE IS200DSFCG1AEB

4. GE IC660BBA020

5. GE DS200DDTBG2A

6. GE IS200DSPXH2DBD

7. GE IC693ACC302

8. GE IS200TRPGH1BDE

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.