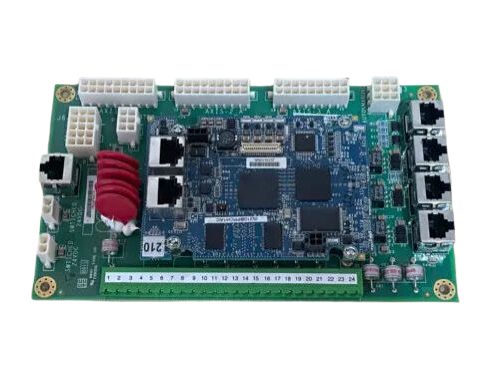

GE FANUC IC697CPM915 Floating Point CPU High Precision Control Module

Introducing the GE FANUC Model: A Pinnacle of Automation Excellence

In the evolving landscape of industrial automation, the GE FANUC stands out as a robust, reliable, and highly versatile solution tailored to meet the demands of modern manufacturing processes. As part of the renowned GE automation products line, this model integrates advanced technology with practical functionality, making it an ideal choice for diverse industrial applications.

Key Technical Features

The GE FANUC is engineered with cutting-edge features that enhance its performance and reliability. At the core of its design is a powerful processing unit that ensures rapid data handling, enabling seamless integration into existing systems. With support for multiple communication protocols, the GE FANUC facilitates easy connectivity with other devices, enhancing interoperability across your automation network.

Among its standout features is the high-speed I/O capability, which allows for real-time monitoring and control. This model also boasts extensive memory options, ensuring ample storage for complex applications. Its user-friendly interface simplifies configuration and operation, reducing downtime and enhancing productivity. Furthermore, the GE FANUC is designed to withstand challenging environments, thanks to its robust construction and compliance with industrial standards.

Usage Scenarios

The versatility of the GE FANUC makes it suitable for a wide range of applications across various sectors. In manufacturing, it can be deployed in assembly lines for precise control of machinery and equipment. Its real-time data processing capabilities enable manufacturers to optimize workflows, reduce waste, and improve overall efficiency.

In the energy sector, the GE FANUC can monitor and control critical systems, ensuring reliable operation of power generation and distribution processes. Its adaptability also makes it an excellent choice for water treatment facilities, where it can manage complex processes and ensure compliance with regulatory standards. From automotive to food processing, the GE FANUC is a dependable partner in achieving automation excellence.

Comparison with Other Models

When compared to other models in the GE lineup, such as the GE SR750 and GE IC697MDL740, the GE FANUC excels in processing speed and I/O capacity. While the SR750 is optimized for specific control tasks, the GE FANUC offers greater flexibility, making it suitable for diverse applications. The GE IS200DSFCG1AEB, known for its specialized functions, may not match the GE FANUC's versatility in various industrial environments.

Moreover, models like the GE IC660BBA020 and GE DS200DDTBG2A focus on specific functionalities, while the GE FANUC serves as a comprehensive solution for automation needs. Its ability to integrate seamlessly with other GE automation products, such as the GE IS200DSPXH2DBD and GE IC693APU301, enhances its utility within an already established GE ecosystem.

Related Models

The GE FANUC is part of a wide array of GE automation products that cater to specific industry needs. Some notable related models include the GE IS200EDFFH1ABA, known for its advanced diagnostics capabilities, and the GE IC695CPE310-ABAH, which features expanded communication options. Other models

The above parameters are for reference only. Please contact our technical team for precise selection.

In the evolving landscape of industrial automation, the GE FANUC stands out as a robust, reliable, and highly versatile solution tailored to meet the demands of modern manufacturing processes. As part of the renowned GE automation products line, this model integrates advanced technology with practical functionality, making it an ideal choice for diverse industrial applications.

Key Technical Features

The GE FANUC is engineered with cutting-edge features that enhance its performance and reliability. At the core of its design is a powerful processing unit that ensures rapid data handling, enabling seamless integration into existing systems. With support for multiple communication protocols, the GE FANUC facilitates easy connectivity with other devices, enhancing interoperability across your automation network.

Among its standout features is the high-speed I/O capability, which allows for real-time monitoring and control. This model also boasts extensive memory options, ensuring ample storage for complex applications. Its user-friendly interface simplifies configuration and operation, reducing downtime and enhancing productivity. Furthermore, the GE FANUC is designed to withstand challenging environments, thanks to its robust construction and compliance with industrial standards.

Usage Scenarios

The versatility of the GE FANUC makes it suitable for a wide range of applications across various sectors. In manufacturing, it can be deployed in assembly lines for precise control of machinery and equipment. Its real-time data processing capabilities enable manufacturers to optimize workflows, reduce waste, and improve overall efficiency.

In the energy sector, the GE FANUC can monitor and control critical systems, ensuring reliable operation of power generation and distribution processes. Its adaptability also makes it an excellent choice for water treatment facilities, where it can manage complex processes and ensure compliance with regulatory standards. From automotive to food processing, the GE FANUC is a dependable partner in achieving automation excellence.

Comparison with Other Models

When compared to other models in the GE lineup, such as the GE SR750 and GE IC697MDL740, the GE FANUC excels in processing speed and I/O capacity. While the SR750 is optimized for specific control tasks, the GE FANUC offers greater flexibility, making it suitable for diverse applications. The GE IS200DSFCG1AEB, known for its specialized functions, may not match the GE FANUC's versatility in various industrial environments.

Moreover, models like the GE IC660BBA020 and GE DS200DDTBG2A focus on specific functionalities, while the GE FANUC serves as a comprehensive solution for automation needs. Its ability to integrate seamlessly with other GE automation products, such as the GE IS200DSPXH2DBD and GE IC693APU301, enhances its utility within an already established GE ecosystem.

Related Models

The GE FANUC is part of a wide array of GE automation products that cater to specific industry needs. Some notable related models include the GE IS200EDFFH1ABA, known for its advanced diagnostics capabilities, and the GE IC695CPE310-ABAH, which features expanded communication options. Other models

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.