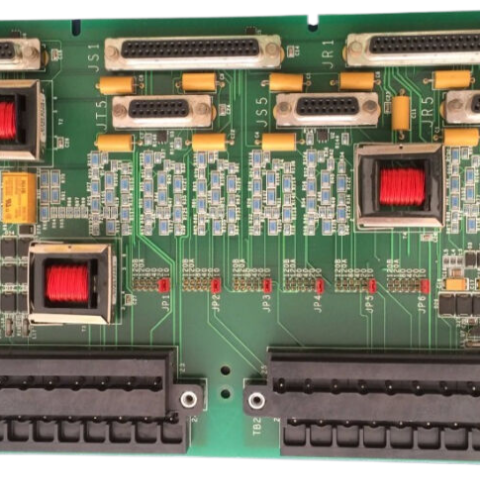

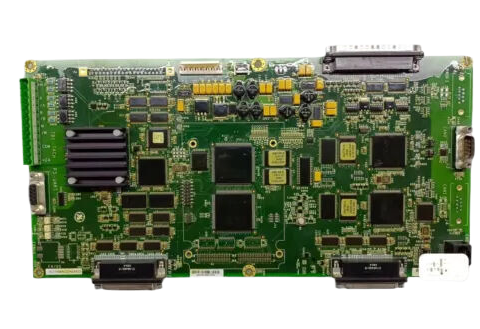

GE FANUC IC200UDR005 28 Point Universal Digital Relay

Introducing the GE FANUC: a pinnacle of reliability and efficiency in the world of automation technology. The GE FANUC series is known for its robust design and exceptional performance, making it a preferred choice for industrial applications across various sectors. Whether you're in manufacturing, energy, or transportation, GE FANUC is engineered to meet the rigorous demands of modern industries.

Key Technical Features

The GE FANUC models are equipped with advanced technical specifications that ensure seamless integration and operation within your automated systems. Key features include high-speed processing capabilities, extensive I/O options, and versatile communication protocols that support both legacy systems and modern networks. The series boasts a powerful CPU that enables real-time processing, ensuring timely decisions and actions within your operational framework. Additionally, GE FANUC products are designed with robust safety features, ensuring compliance with industry standards while safeguarding your operations.

The user-friendly programming environment of GE FANUC products allows for quick and efficient setup, reducing downtime and enhancing productivity. With compatibility for various programming languages, users can easily adapt the system to their specific needs. Moreover, GE FANUC's modular design facilitates easy expansion, allowing businesses to scale their operations without replacing existing infrastructure.

Usage Scenarios

GE FANUC automation products are ideal for a variety of applications. In manufacturing, they can be utilized for controlling assembly lines, monitoring production processes, and ensuring quality control. The flexibility of GE FANUC makes it suitable for both discrete and process manufacturing environments, enabling manufacturers to streamline operations and enhance productivity.

In the energy sector, GE FANUC models can be employed for real-time monitoring and control of power generation and distribution systems. Their ability to handle vast amounts of data ensures that energy operators can make informed decisions quickly, optimizing resource management and enhancing system reliability.

Transportation systems also benefit from GE FANUC technology. From traffic management to railway control systems, the reliability and efficiency of GE FANUC products ensure smooth operations, minimizing delays and enhancing safety.

Comparison with Other Models

When compared to other models within the GE portfolio, such as the GE SR750 or GE IC697MDL740, the GE FANUC series stands out for its advanced processing capabilities and modular approach. While the GE SR750 is renowned for its high-performance data processing, GE FANUC offers a more versatile solution that caters to a wider range of applications. Similarly, when placed alongside the GE IS200DSPXH2DBD and other models, the GE FANUC’s adaptability and ease of integration make it a superior choice for companies looking to modernize their automation systems without a complete overhaul.

For businesses seeking specific functionalities, models like the GE IC695CPE310-ABAH and GE IS200TRPGH1BDE also provide valuable options. However, the comprehensive features and scalability of the GE FANUC series often provide a more holistic solution for diverse operational needs.

Related Models

When considering the GE FANUC series, it’s important to also look at related models that may suit your specific requirements. These include the GE IC693APU301

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features

The GE FANUC models are equipped with advanced technical specifications that ensure seamless integration and operation within your automated systems. Key features include high-speed processing capabilities, extensive I/O options, and versatile communication protocols that support both legacy systems and modern networks. The series boasts a powerful CPU that enables real-time processing, ensuring timely decisions and actions within your operational framework. Additionally, GE FANUC products are designed with robust safety features, ensuring compliance with industry standards while safeguarding your operations.

The user-friendly programming environment of GE FANUC products allows for quick and efficient setup, reducing downtime and enhancing productivity. With compatibility for various programming languages, users can easily adapt the system to their specific needs. Moreover, GE FANUC's modular design facilitates easy expansion, allowing businesses to scale their operations without replacing existing infrastructure.

Usage Scenarios

GE FANUC automation products are ideal for a variety of applications. In manufacturing, they can be utilized for controlling assembly lines, monitoring production processes, and ensuring quality control. The flexibility of GE FANUC makes it suitable for both discrete and process manufacturing environments, enabling manufacturers to streamline operations and enhance productivity.

In the energy sector, GE FANUC models can be employed for real-time monitoring and control of power generation and distribution systems. Their ability to handle vast amounts of data ensures that energy operators can make informed decisions quickly, optimizing resource management and enhancing system reliability.

Transportation systems also benefit from GE FANUC technology. From traffic management to railway control systems, the reliability and efficiency of GE FANUC products ensure smooth operations, minimizing delays and enhancing safety.

Comparison with Other Models

When compared to other models within the GE portfolio, such as the GE SR750 or GE IC697MDL740, the GE FANUC series stands out for its advanced processing capabilities and modular approach. While the GE SR750 is renowned for its high-performance data processing, GE FANUC offers a more versatile solution that caters to a wider range of applications. Similarly, when placed alongside the GE IS200DSPXH2DBD and other models, the GE FANUC’s adaptability and ease of integration make it a superior choice for companies looking to modernize their automation systems without a complete overhaul.

For businesses seeking specific functionalities, models like the GE IC695CPE310-ABAH and GE IS200TRPGH1BDE also provide valuable options. However, the comprehensive features and scalability of the GE FANUC series often provide a more holistic solution for diverse operational needs.

Related Models

When considering the GE FANUC series, it’s important to also look at related models that may suit your specific requirements. These include the GE IC693APU301

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.