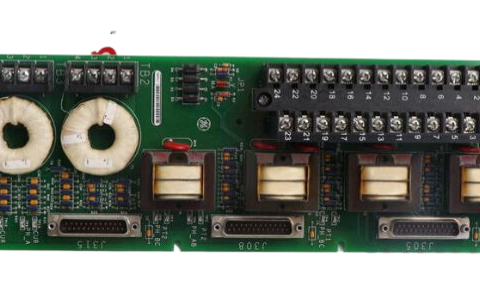

GE Fanuc 8601-FT-NI Field Terminal Industrial Communication Module for Enhanced Efficiency and Reliability

Introducing the GE Fanuc: A Pinnacle of Automation Technology

In the rapidly evolving landscape of industrial automation, the GE Fanuc model stands out as a premier choice for engineers and businesses seeking reliability, efficiency, and advanced functionality. This cutting-edge product combines state-of-the-art technology with user-friendly features, making it an essential component of any automation strategy.

Key Technical Features

The GE Fanuc is engineered with a robust feature set designed to meet the demands of modern industrial applications. It is equipped with high-performance processors that ensure swift processing times and superior data handling capabilities. With multiple communication protocols integrated into its architecture, the GE Fanuc facilitates seamless connectivity across various systems, reinforcing its status as a versatile tool in the realm of GE automation products.

The device supports extensive input and output capabilities, making it ideal for complex control tasks. Its modular design allows for easy scalability, enabling users to expand their systems as their operational needs grow. Additionally, the GE Fanuc is compatible with various software solutions, ensuring that it can be integrated into existing setups without a hitch.

Usage Scenarios

The GE Fanuc is predominantly used in manufacturing facilities, energy production plants, and various sectors where automation plays a critical role. For instance, in a manufacturing environment, the GE Fanuc can manage assembly lines, controlling robotic systems and monitoring production efficiencies in real-time. Its ability to gather and analyze data enhances decision-making processes, allowing for timely adjustments to prevent downtime and increase productivity.

In the energy sector, the GE Fanuc excels in controlling and monitoring power generation equipment, ensuring optimal performance and reliability. It provides operators with the ability to remotely access system diagnostics and analytics, resulting in proactive maintenance and reduced operational costs.

Comparison with Other Models

When compared to other models within the GE portfolio, such as the GE SR750 and GE IS200DSPXH2DBD, the GE Fanuc offers a more versatile communication setup, allowing it to integrate seamlessly into diverse industrial environments. While the GE SR750 is focused on specific applications with limited I/O capabilities, the GE Fanuc excels in its modularity and scalability, making it suitable for larger and more complex systems.

Additionally, compared to the GE IC695CPE310-ABAH and GE IS200EDFFH1ABA, the GE Fanuc provides a more user-friendly interface, streamlining operation for technicians and engineers alike. Its design emphasizes ease of use without sacrificing performance, making it a preferred choice among automation professionals.

Related Models

The GE Fanuc can be effectively utilized alongside a variety of related models, including the GE IC697MDL740, GE IS200DSFCG1AEB, GE DS200DDTBG2A, GE IC200CPU005, GE IC3600A0AHIC, GE IC695LRE001B, GE IS200JPDMG1ADC, GE VMIVME-7671-421000, GE 469-P5-HI-A1-E-H, and GE DS200SIO

The above parameters are for reference only. Please contact our technical team for precise selection.

In the rapidly evolving landscape of industrial automation, the GE Fanuc model stands out as a premier choice for engineers and businesses seeking reliability, efficiency, and advanced functionality. This cutting-edge product combines state-of-the-art technology with user-friendly features, making it an essential component of any automation strategy.

Key Technical Features

The GE Fanuc is engineered with a robust feature set designed to meet the demands of modern industrial applications. It is equipped with high-performance processors that ensure swift processing times and superior data handling capabilities. With multiple communication protocols integrated into its architecture, the GE Fanuc facilitates seamless connectivity across various systems, reinforcing its status as a versatile tool in the realm of GE automation products.

The device supports extensive input and output capabilities, making it ideal for complex control tasks. Its modular design allows for easy scalability, enabling users to expand their systems as their operational needs grow. Additionally, the GE Fanuc is compatible with various software solutions, ensuring that it can be integrated into existing setups without a hitch.

Usage Scenarios

The GE Fanuc is predominantly used in manufacturing facilities, energy production plants, and various sectors where automation plays a critical role. For instance, in a manufacturing environment, the GE Fanuc can manage assembly lines, controlling robotic systems and monitoring production efficiencies in real-time. Its ability to gather and analyze data enhances decision-making processes, allowing for timely adjustments to prevent downtime and increase productivity.

In the energy sector, the GE Fanuc excels in controlling and monitoring power generation equipment, ensuring optimal performance and reliability. It provides operators with the ability to remotely access system diagnostics and analytics, resulting in proactive maintenance and reduced operational costs.

Comparison with Other Models

When compared to other models within the GE portfolio, such as the GE SR750 and GE IS200DSPXH2DBD, the GE Fanuc offers a more versatile communication setup, allowing it to integrate seamlessly into diverse industrial environments. While the GE SR750 is focused on specific applications with limited I/O capabilities, the GE Fanuc excels in its modularity and scalability, making it suitable for larger and more complex systems.

Additionally, compared to the GE IC695CPE310-ABAH and GE IS200EDFFH1ABA, the GE Fanuc provides a more user-friendly interface, streamlining operation for technicians and engineers alike. Its design emphasizes ease of use without sacrificing performance, making it a preferred choice among automation professionals.

Related Models

The GE Fanuc can be effectively utilized alongside a variety of related models, including the GE IC697MDL740, GE IS200DSFCG1AEB, GE DS200DDTBG2A, GE IC200CPU005, GE IC3600A0AHIC, GE IC695LRE001B, GE IS200JPDMG1ADC, GE VMIVME-7671-421000, GE 469-P5-HI-A1-E-H, and GE DS200SIO

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.