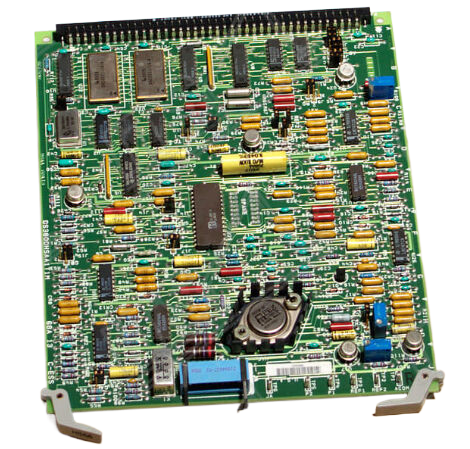

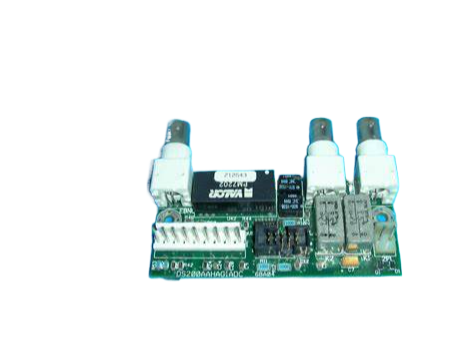

GE Fanuc HE693IBS100 Modular Control System

Introducing the GE Fanuc, a pinnacle of innovation in industrial automation and control solutions. As part of the esteemed GE family, the GE Fanuc model stands out for its exceptional performance, reliability, and versatility, making it an essential component for various industries aiming to enhance their operational efficiency.

Key Technical Features:

The GE Fanuc model is engineered with cutting-edge technology, ensuring high performance and durability. It offers advanced processing capabilities with robust communication protocols that facilitate seamless integration into existing systems. The model features a scalable architecture, allowing businesses to adapt and expand their automation systems as needed. With multiple I/O options, the GE Fanuc provides flexibility in configuration, catering to a wide range of applications. It also incorporates real-time diagnostics, which enables prompt troubleshooting and maintenance, thereby minimizing downtime.

The GE Fanuc model excels in enhancing data acquisition and control through its high-speed processing capabilities. Users can expect precise control over machinery and processes, thanks to its accurate analog and digital input/output options. The system is designed for ease of use, featuring intuitive software tools that streamline programming and configuration, making it accessible for both seasoned engineers and newcomers alike.

Usage Scenarios:

The versatility of the GE Fanuc model makes it suitable for various applications across multiple sectors, including manufacturing, energy, transportation, and infrastructure. In manufacturing, the GE Fanuc can manage complex assembly lines, ensuring precision and efficiency in production processes. In the energy sector, it can facilitate real-time monitoring and control of power generation systems, enhancing overall reliability.

In transportation, the GE Fanuc model can be employed in traffic management systems, optimizing flow and reducing congestion. Additionally, in infrastructure projects, it can oversee critical systems such as water treatment plants, ensuring compliance with environmental standards while maximizing operational efficiency.

Comparison with Other Models:

When compared to other models within the GE lineup, such as the GE SR750 and GE IC697MDL740, the GE Fanuc model offers enhanced processing speed and expanded connectivity options. While the GE IC200CPU005 is effective for smaller applications, the GE Fanuc is designed for more complex systems requiring higher performance. Unlike the GE IS200DSFCG1AEB, which is tailored for specialized applications, the GE Fanuc provides a broader range of functionalities, making it a more versatile choice.

In contrast to models like the GE IS200DSPXH2DBD and GE IC693APU301, the GE Fanuc excels in real-time data handling, making it ideal for industries where responsiveness is crucial. Its competitive edge lies in its ability to integrate seamlessly with other GE automation products, enhancing overall system performance.

Related Models:

For those exploring additional options within the GE automation products range, consider the following related models: GE IS200EDFFH1ABA, GE DS200DDTBG2A, GE IC694PWR331, GE IC660BBA020, GE IS200TRPGH1BDE, GE DS200TCDAH1BHD, GE IC200UAL005

The above parameters are for reference only. Please contact our technical team for precise selection.

Key Technical Features:

The GE Fanuc model is engineered with cutting-edge technology, ensuring high performance and durability. It offers advanced processing capabilities with robust communication protocols that facilitate seamless integration into existing systems. The model features a scalable architecture, allowing businesses to adapt and expand their automation systems as needed. With multiple I/O options, the GE Fanuc provides flexibility in configuration, catering to a wide range of applications. It also incorporates real-time diagnostics, which enables prompt troubleshooting and maintenance, thereby minimizing downtime.

The GE Fanuc model excels in enhancing data acquisition and control through its high-speed processing capabilities. Users can expect precise control over machinery and processes, thanks to its accurate analog and digital input/output options. The system is designed for ease of use, featuring intuitive software tools that streamline programming and configuration, making it accessible for both seasoned engineers and newcomers alike.

Usage Scenarios:

The versatility of the GE Fanuc model makes it suitable for various applications across multiple sectors, including manufacturing, energy, transportation, and infrastructure. In manufacturing, the GE Fanuc can manage complex assembly lines, ensuring precision and efficiency in production processes. In the energy sector, it can facilitate real-time monitoring and control of power generation systems, enhancing overall reliability.

In transportation, the GE Fanuc model can be employed in traffic management systems, optimizing flow and reducing congestion. Additionally, in infrastructure projects, it can oversee critical systems such as water treatment plants, ensuring compliance with environmental standards while maximizing operational efficiency.

Comparison with Other Models:

When compared to other models within the GE lineup, such as the GE SR750 and GE IC697MDL740, the GE Fanuc model offers enhanced processing speed and expanded connectivity options. While the GE IC200CPU005 is effective for smaller applications, the GE Fanuc is designed for more complex systems requiring higher performance. Unlike the GE IS200DSFCG1AEB, which is tailored for specialized applications, the GE Fanuc provides a broader range of functionalities, making it a more versatile choice.

In contrast to models like the GE IS200DSPXH2DBD and GE IC693APU301, the GE Fanuc excels in real-time data handling, making it ideal for industries where responsiveness is crucial. Its competitive edge lies in its ability to integrate seamlessly with other GE automation products, enhancing overall system performance.

Related Models:

For those exploring additional options within the GE automation products range, consider the following related models: GE IS200EDFFH1ABA, GE DS200DDTBG2A, GE IC694PWR331, GE IC660BBA020, GE IS200TRPGH1BDE, GE DS200TCDAH1BHD, GE IC200UAL005

The above parameters are for reference only. Please contact our technical team for precise selection.

There are no reviews yet.